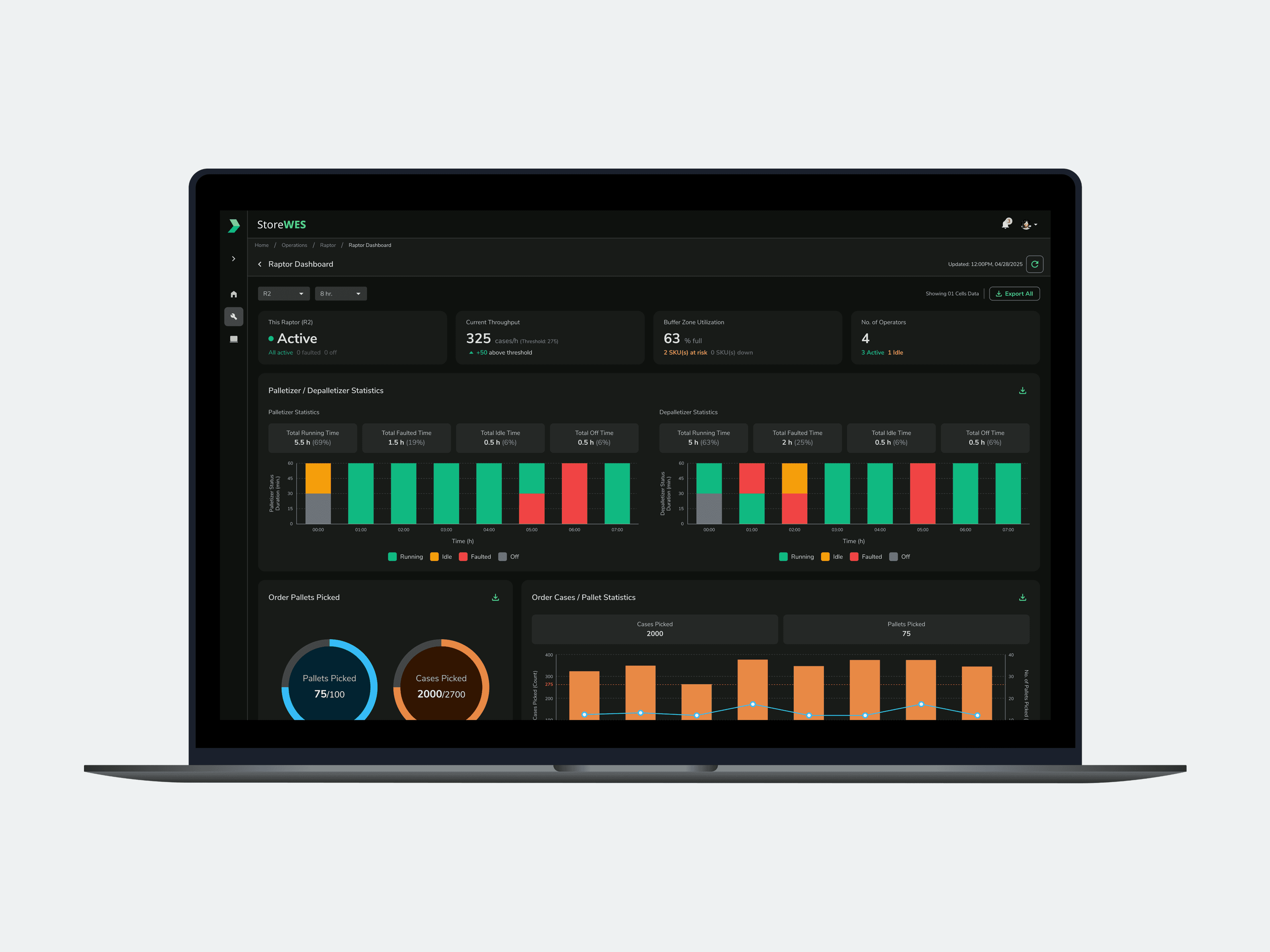

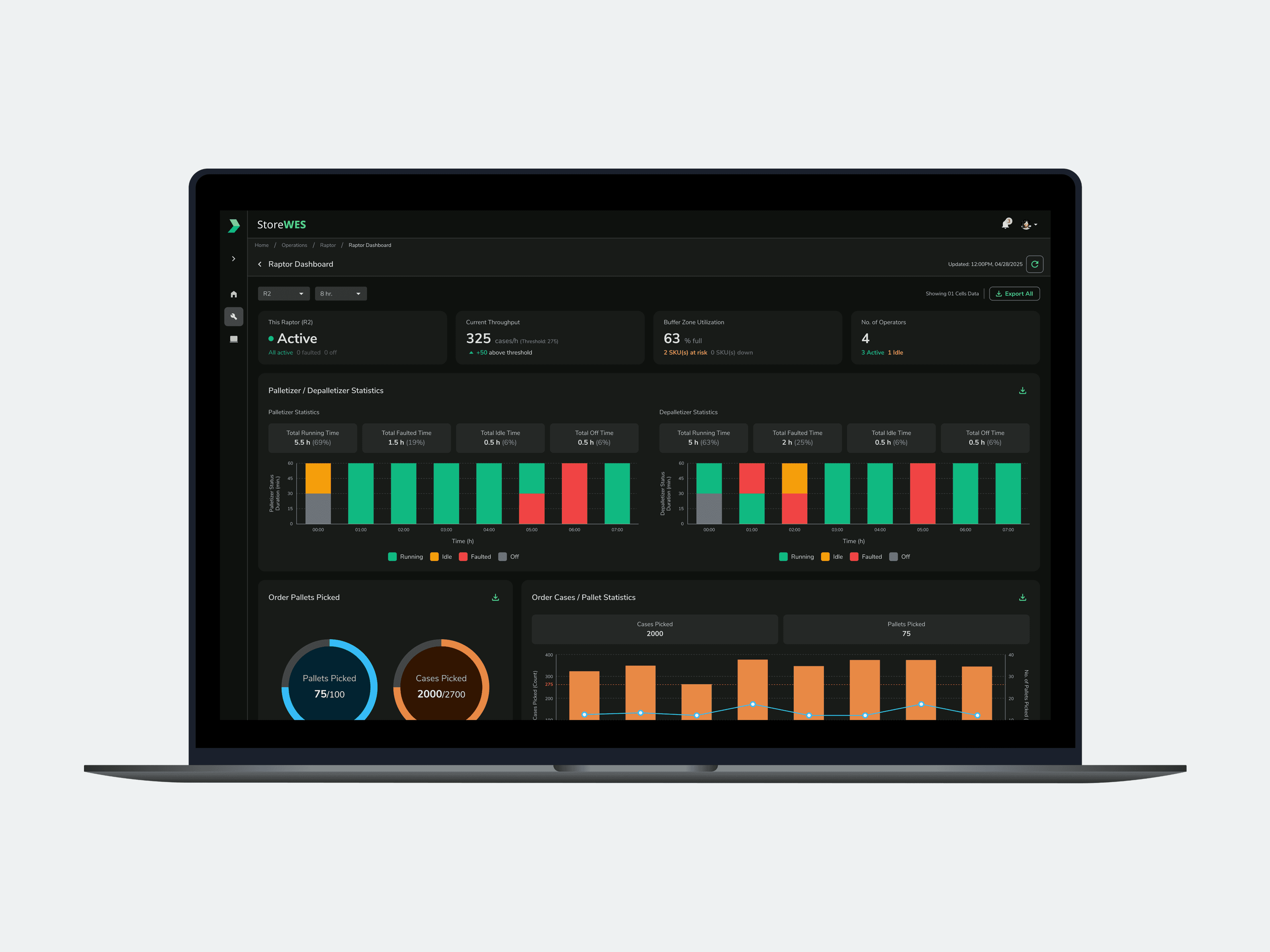

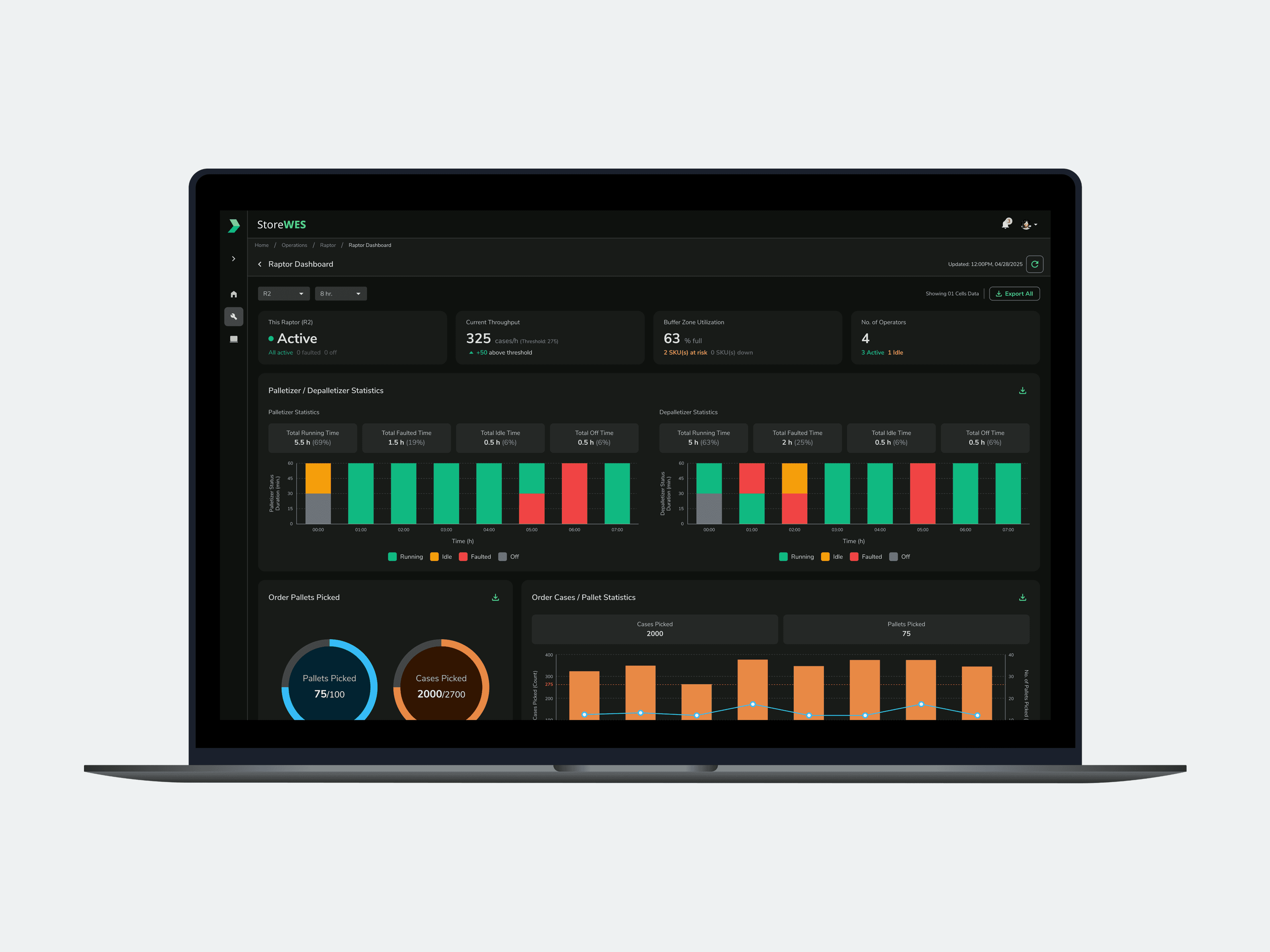

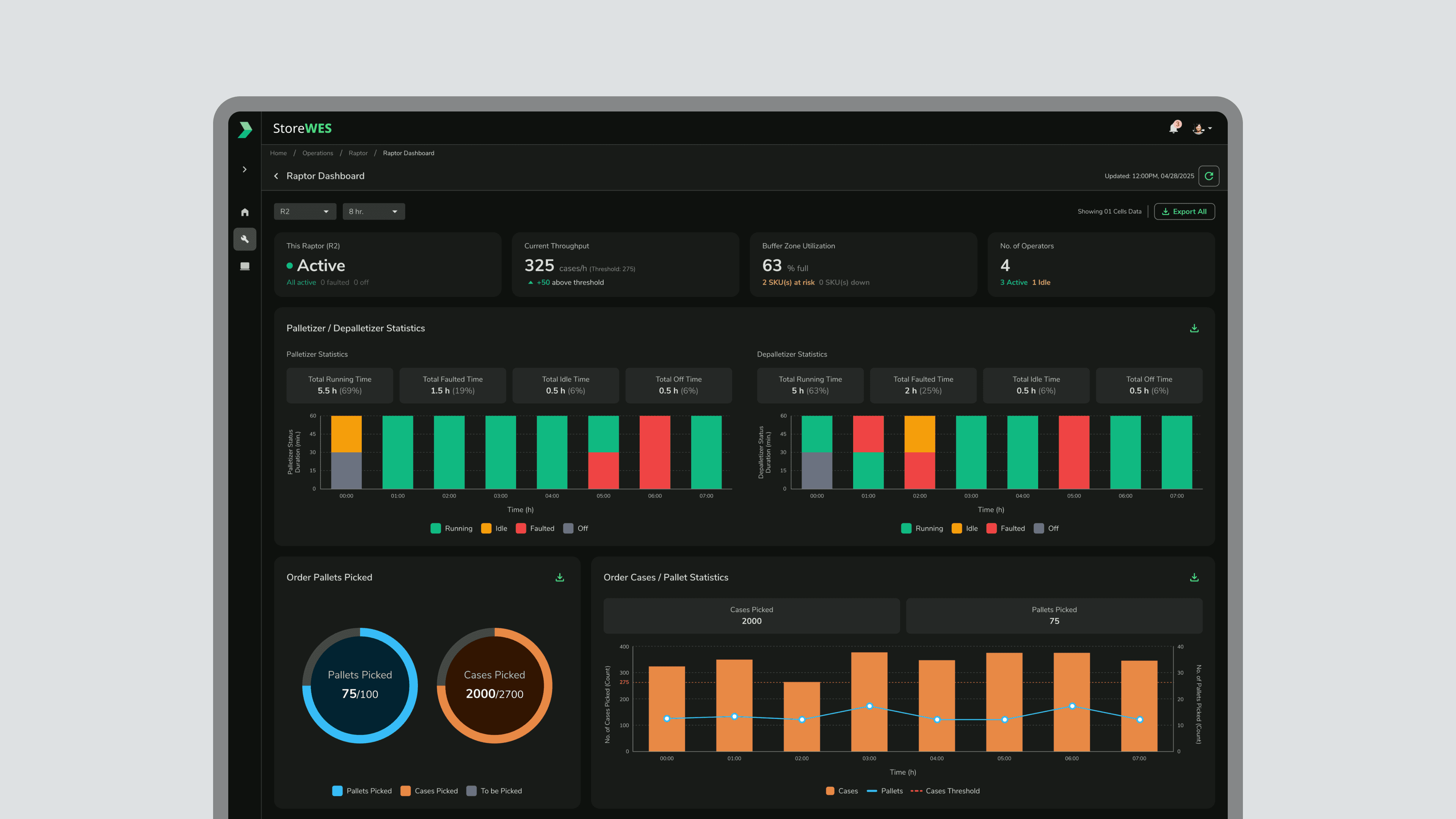

Making Robotic Fulfillment Understandable for Warehouse Supervisors

Designing clear, actionable insights that help supervisors monitor, understand, and manage robotic operations with confidence.

Role

Product Designer

Industry

Logistics

Duration

1 month

Overview

Overview

Context

StoreSolutions is a US-based B2B warehousing solutions provider building automation systems for fulfillment centers. They were launching RAPTOR (Robotic Arm Picking To Order Release), a robotic picking system that uses robotic arms to pick cases from inbound pallets and build outbound order pallets.

While the designs included operator, admin, and RF workflows, this project focuses specifically on the design of the operations dashboard that gives managers a real-time, shift-level view of RAPTOR performance.

Note: StoreSolutions is a pseudonym. The actual client name has been replaced in this project to protect client confidentiality.

Context

StoreSolutions is a US-based B2B warehousing solutions provider building automation systems for fulfillment centers. They were launching RAPTOR (Robotic Arm Picking To Order Release), a robotic picking system that uses robotic arms to pick cases from inbound pallets and build outbound order pallets.

While the designs included operator, admin, and RF workflows, this project focuses specifically on the design of the operations dashboard that gives managers a real-time, shift-level view of RAPTOR performance.

Note: StoreSolutions is a pseudonym. The actual client name has been replaced in this project to protect client confidentiality.

Problem

Warehouse managers needed a clear way to monitor RAPTOR system performance during fast-paced, high-volume operations, where small issues could quickly impact throughput.

The challenge was to design a dashboard that enabled quick understanding and early issue detection while keeping cognitive load low in a complex, real-time environment.

Problem

Warehouse managers needed a clear way to monitor RAPTOR system performance during fast-paced, high-volume operations, where small issues could quickly impact throughput.

The challenge was to design a dashboard that enabled quick understanding and early issue detection while keeping cognitive load low in a complex, real-time environment.

Outcome & Impact

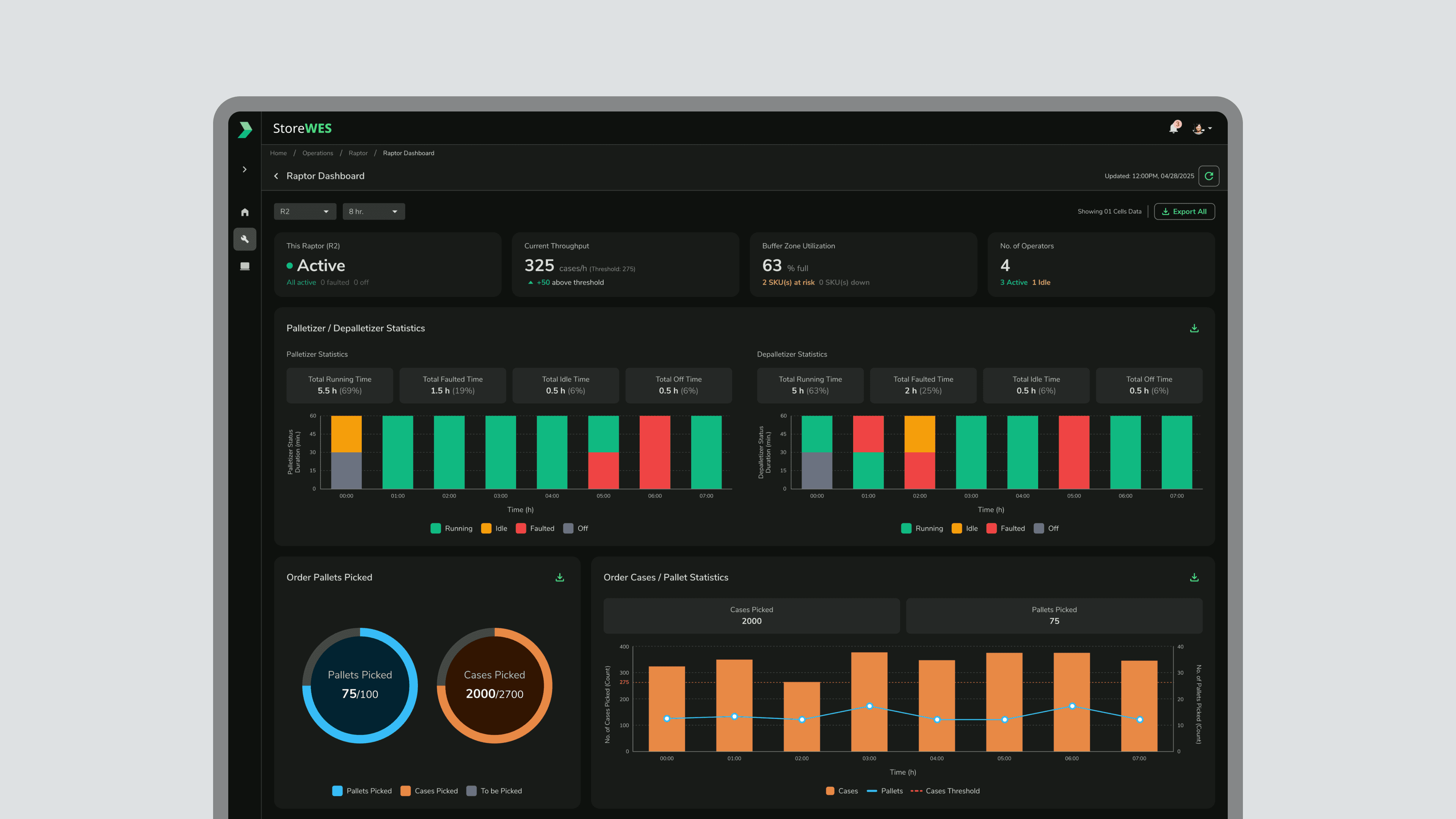

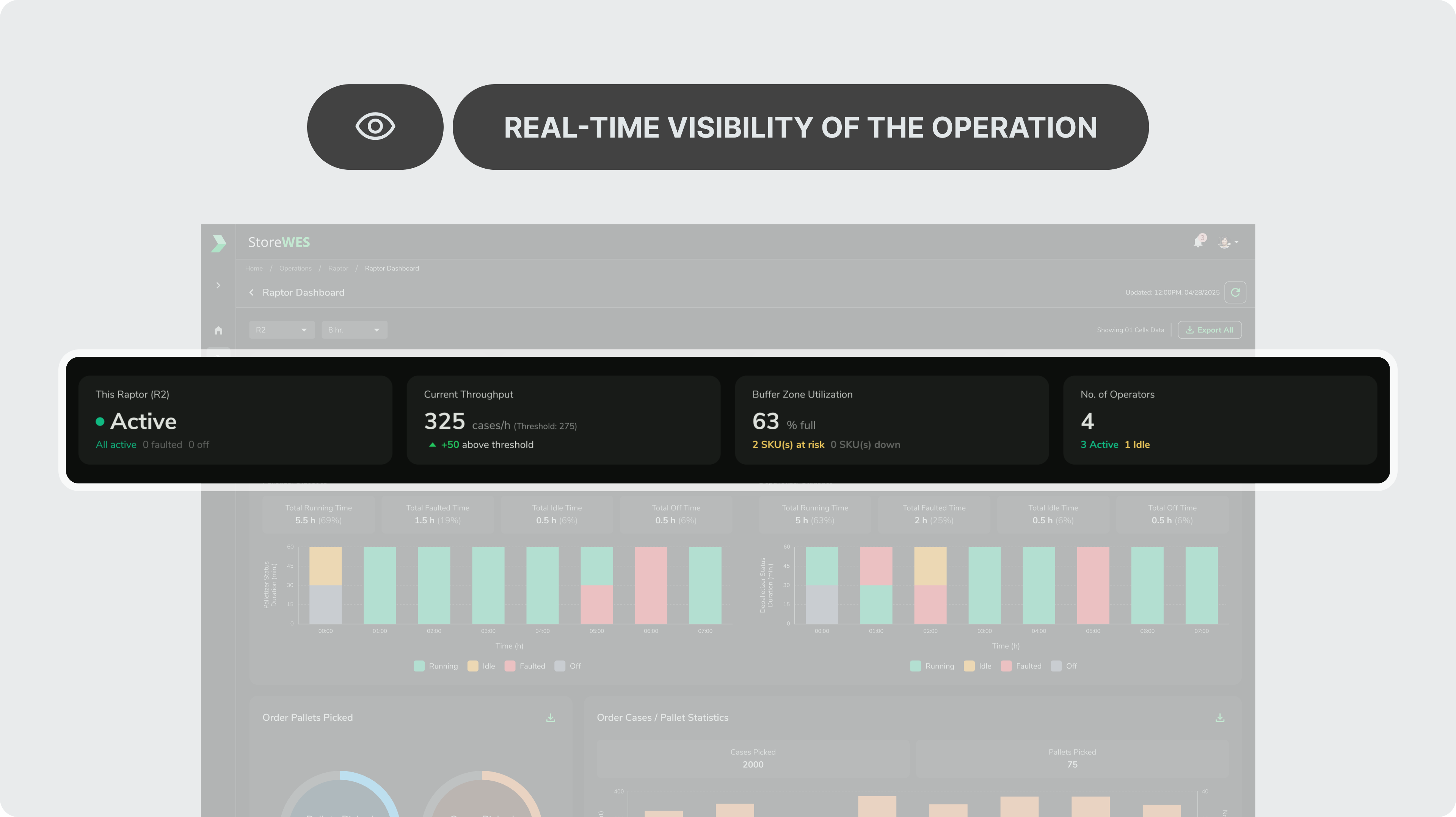

Designed a real-time operations dashboard that surfaces critical shift-level KPIs, system status, and performance trends across RAPTOR cells, enabling managers to understand system health at a glance and drill down when needed.

Enabled faster situational awareness by separating primary KPIs (quick glance) from detailed performance metrics

Reduced cognitive load during live operations through clear hierarchy, thresholds, and time-based views

Supported earlier issue detection (throughput drops, idle/fault states) before they impacted order completion

Outcome & Impact

Designed a real-time operations dashboard that surfaces critical shift-level KPIs, system status, and performance trends across RAPTOR cells, enabling managers to understand system health at a glance and drill down when needed.

Enabled faster situational awareness by separating primary KPIs (quick glance) from detailed performance metrics

Reduced cognitive load during live operations through clear hierarchy, thresholds, and time-based views

Supported earlier issue detection (throughput drops, idle/fault states) before they impacted order completion

Research Insights

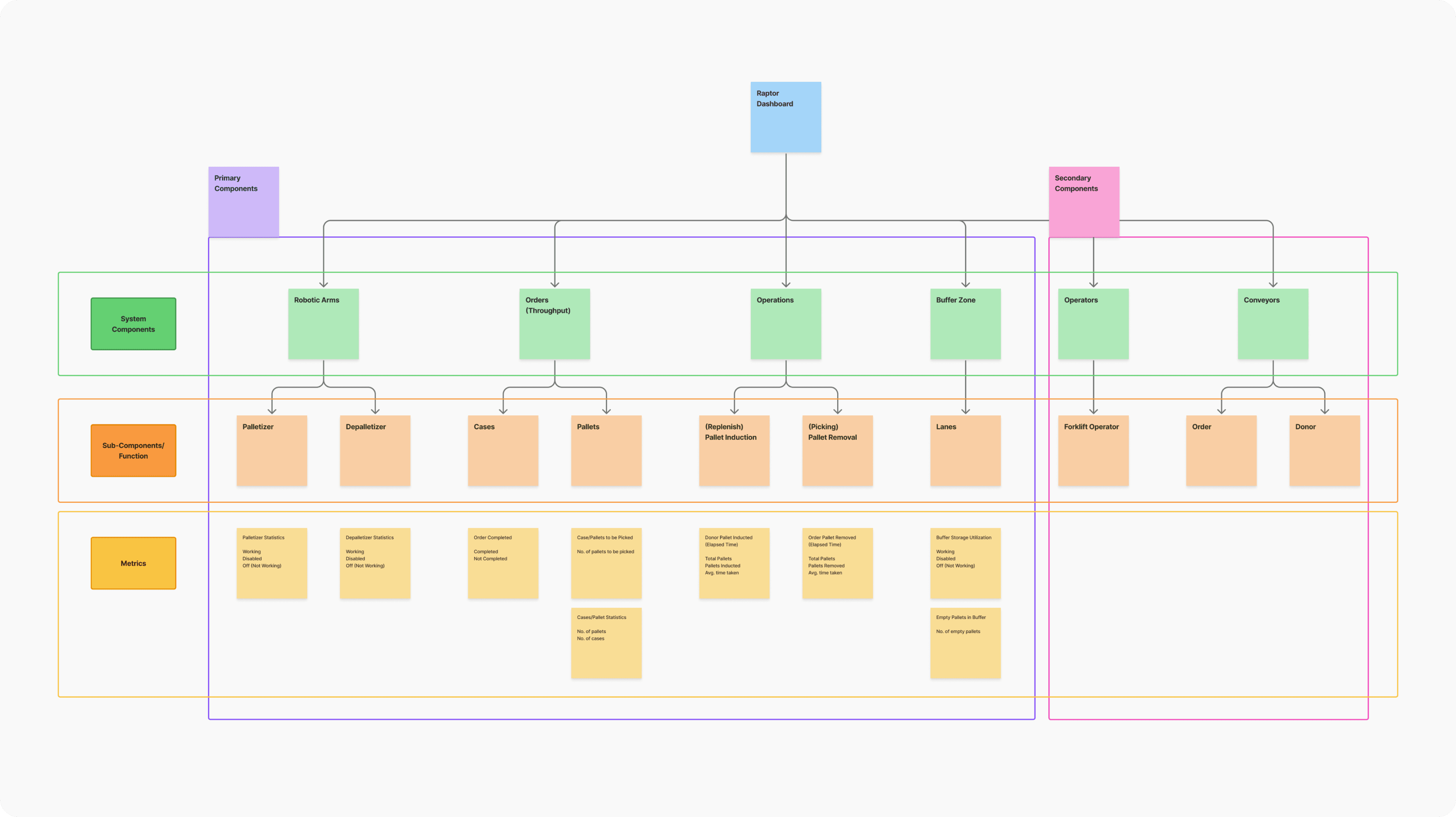

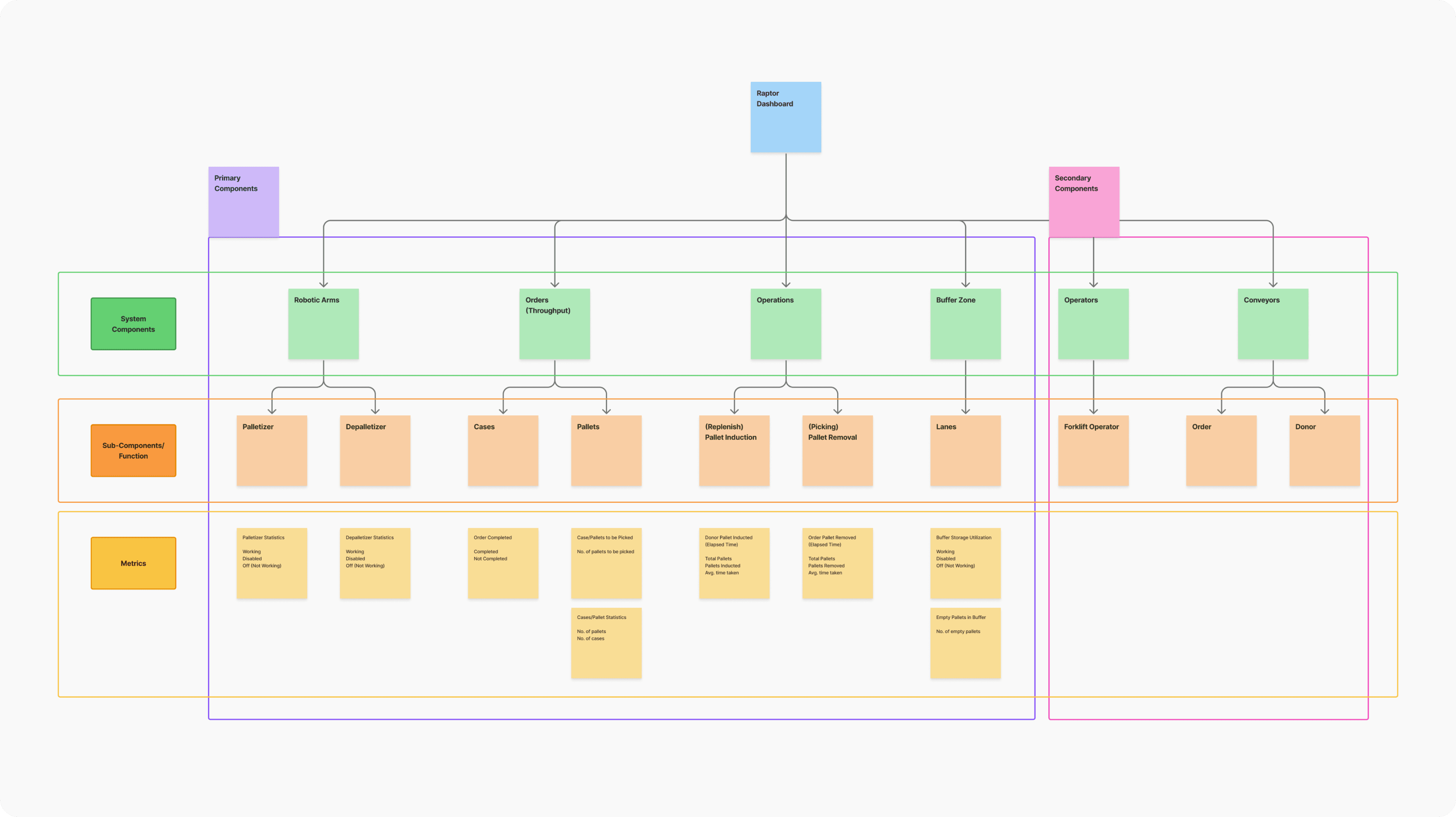

Research was conducted during the early discovery phase to understand how warehouse teams monitor and manage Raptor robotic cells during live operations. Deep dive discussions with the Product Manager guided the insights and understanding.

Key Insights:

This dashboard is supposed to serve monitoring purpose for the warehouse manager.

Managers need to understand health status, alert visibility and productivity of the system through this dashboard.

System state matters the most as managers need clear visibility of Running, Idle, Faulted, and Off states to ensure smooth operation.

Key responsibility of the Raptor system is to track 'order pallets', not 'orders'.

For better context cases and pallets must be viewed together.

Research Insights

Research was conducted during the early discovery phase to understand how warehouse teams monitor and manage Raptor robotic cells during live operations. Deep dive discussions with the Product Manager guided the insights and understanding.

Key Insights:

This dashboard is supposed to serve monitoring purpose for the warehouse manager.

Managers need to understand health status, alert visibility and productivity of the system through this dashboard.

System state matters the most as managers need clear visibility of Running, Idle, Faulted, and Off states to ensure smooth operation.

Key responsibility of the Raptor system is to track 'order pallets', not 'orders'.

For better context cases and pallets must be viewed together.

Solution Highlights

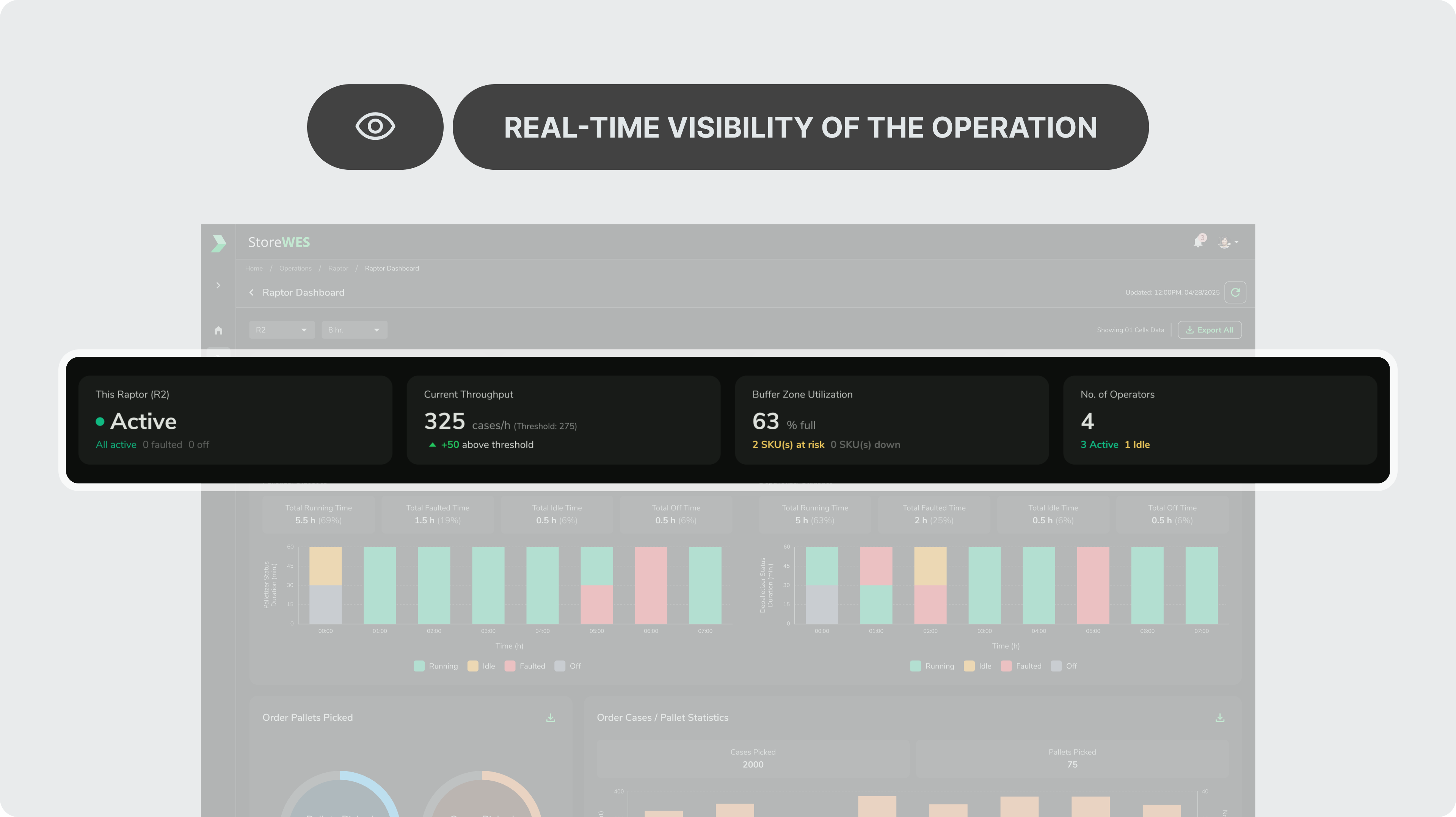

Real-Time Operational Awareness: High-signal primary KPIs enable instant understanding of system status without cognitive overhead.

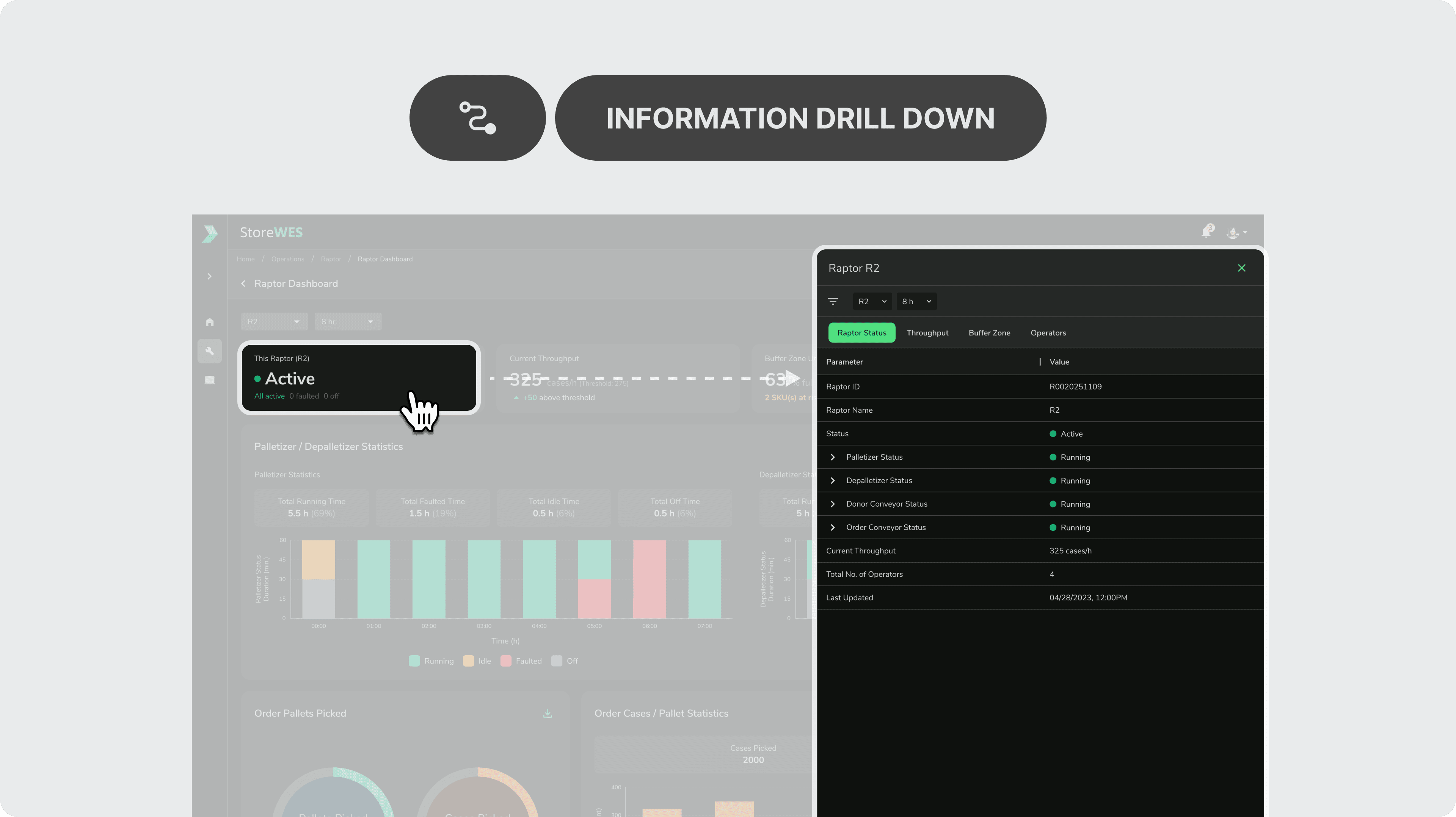

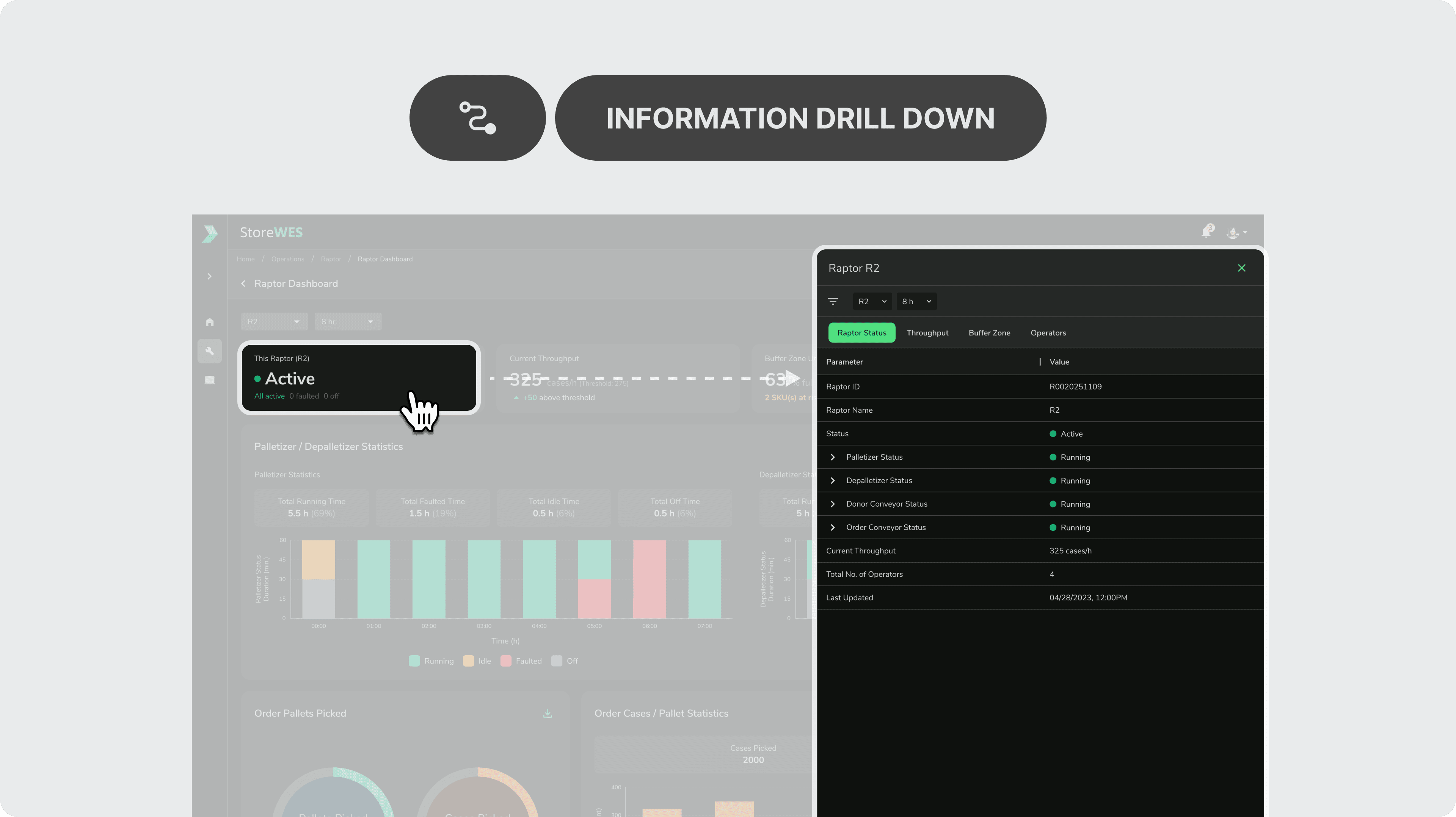

2. Progressive Drill-Down: Seamless transition from high-level health indicators to detailed system insights supports faster investigation.

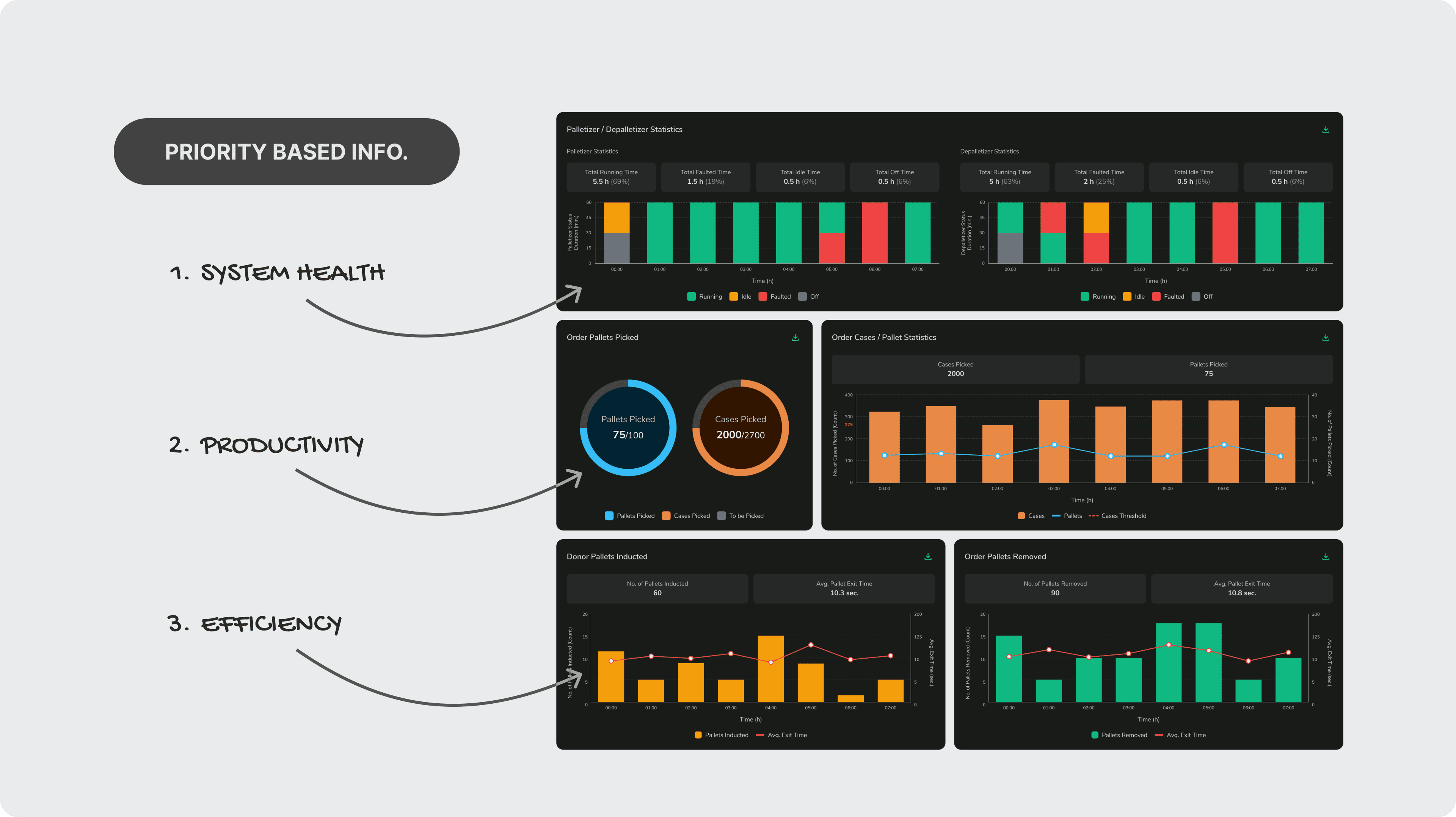

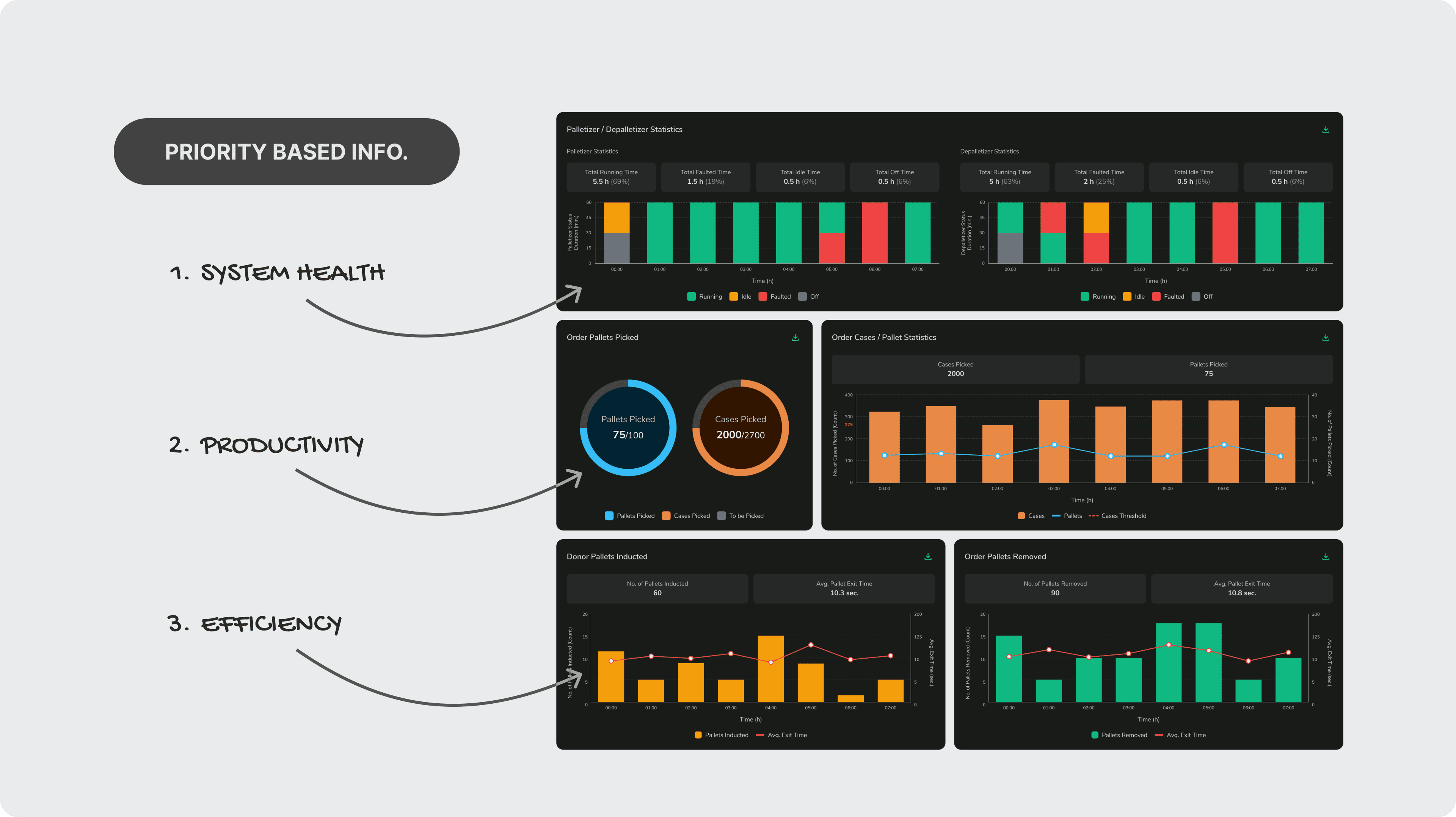

Priority-Based Information Structure: Operational data is organized by decision urgency—system health first, productivity next, efficiency last.

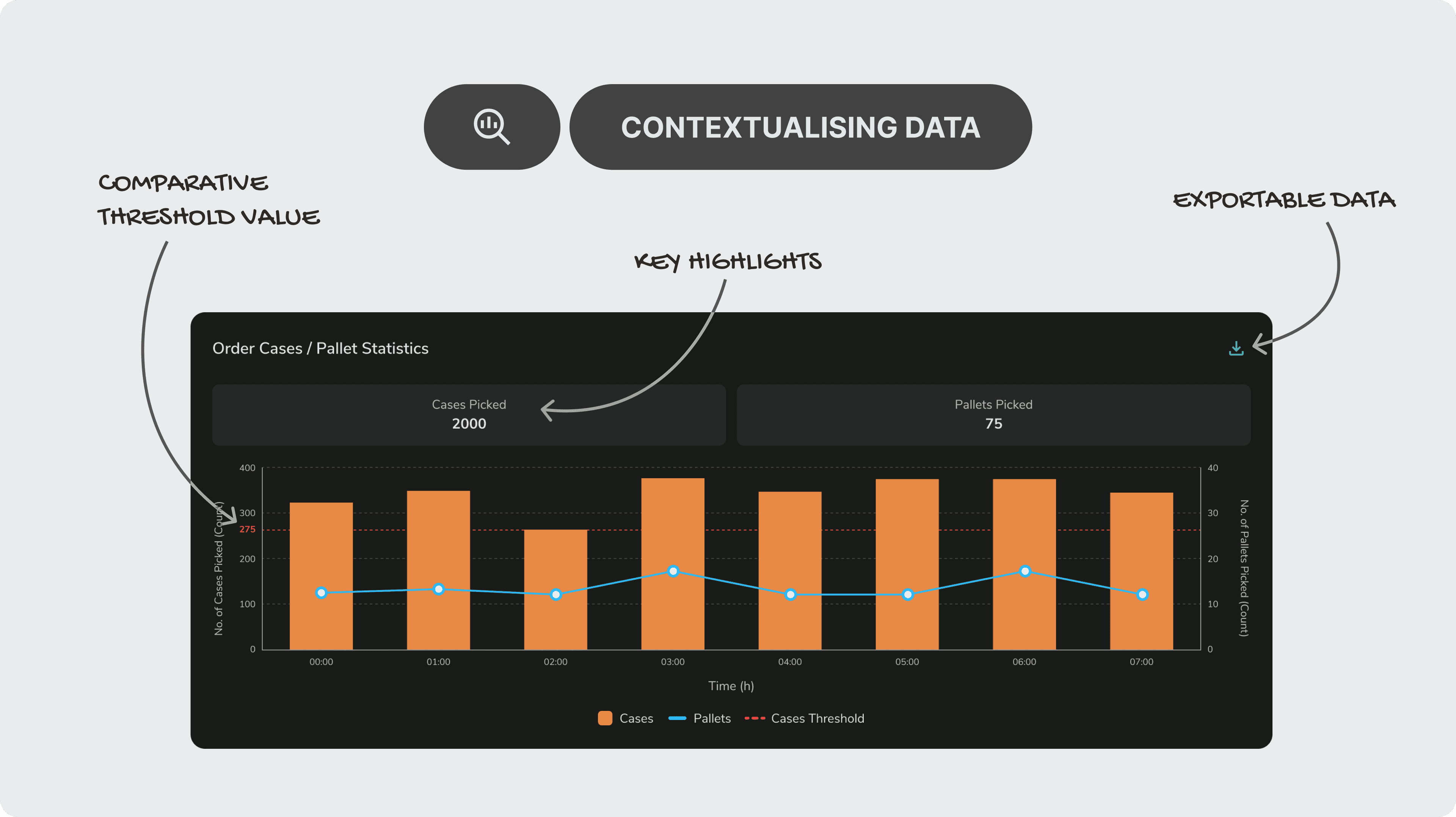

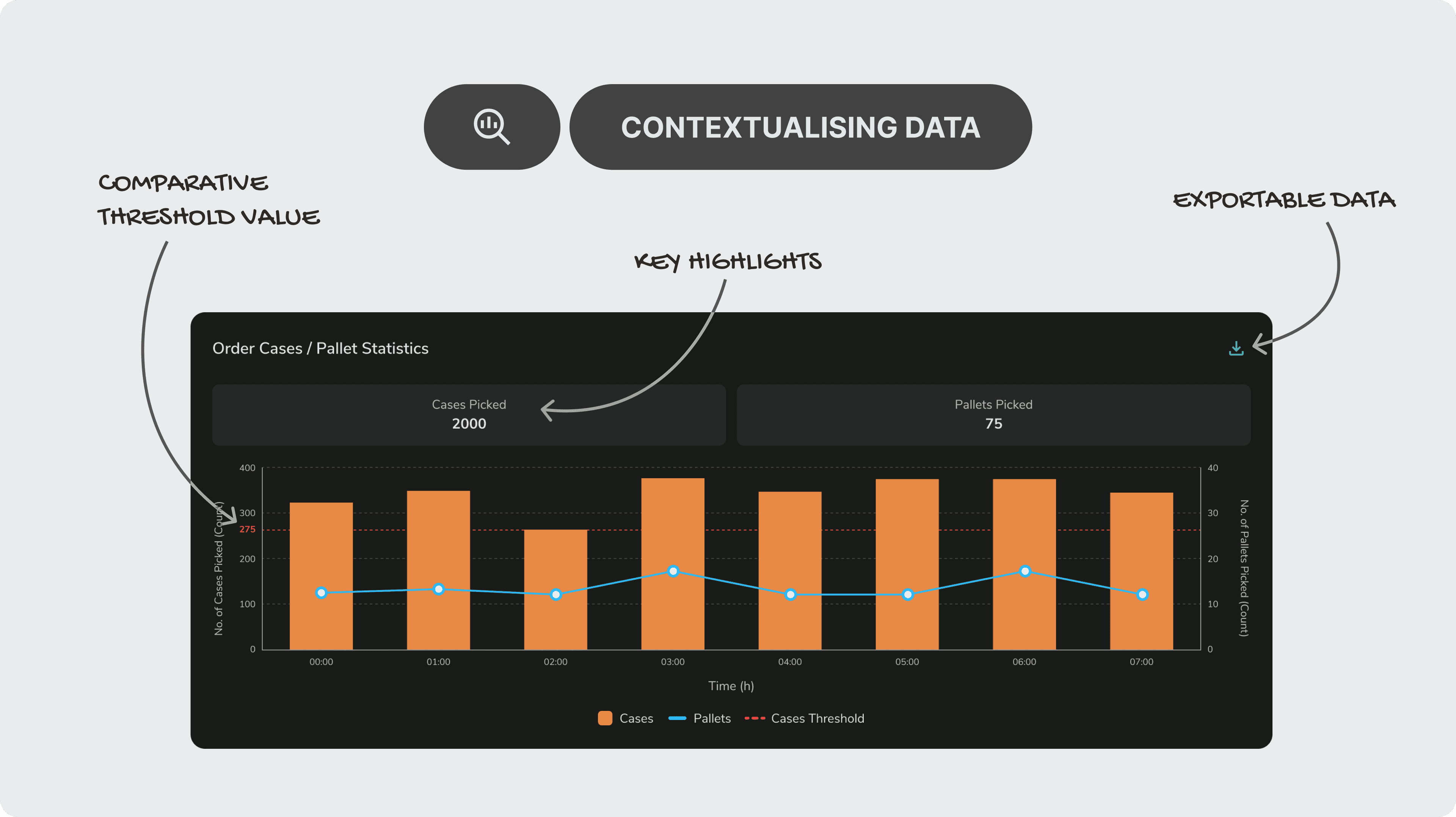

Contextualized Performance Metrics: Thresholds, highlights, and exports frame raw data into actionable operational context.

Solution Highlights

Real-Time Operational Awareness: High-signal primary KPIs enable instant understanding of system status without cognitive overhead.

2. Progressive Drill-Down: Seamless transition from high-level health indicators to detailed system insights supports faster investigation.

Priority-Based Information Structure: Operational data is organized by decision urgency—system health first, productivity next, efficiency last.

Contextualized Performance Metrics: Thresholds, highlights, and exports frame raw data into actionable operational context.

Learnings

Design advocacy through system understanding: Reframed BRD-driven requirements with clearer hierarchy and decision-focused KPIs aligned to real operational needs.

Designing for decision velocity: Operations dashboards must prioritize speed of understanding over completeness, surfacing the right signals first and deferring detail until it’s needed.

Designing for multi-entity scalability: Learned to design components that scale from a single cell to multiple RAPTOR systems without changing mental models for users.

Other projects

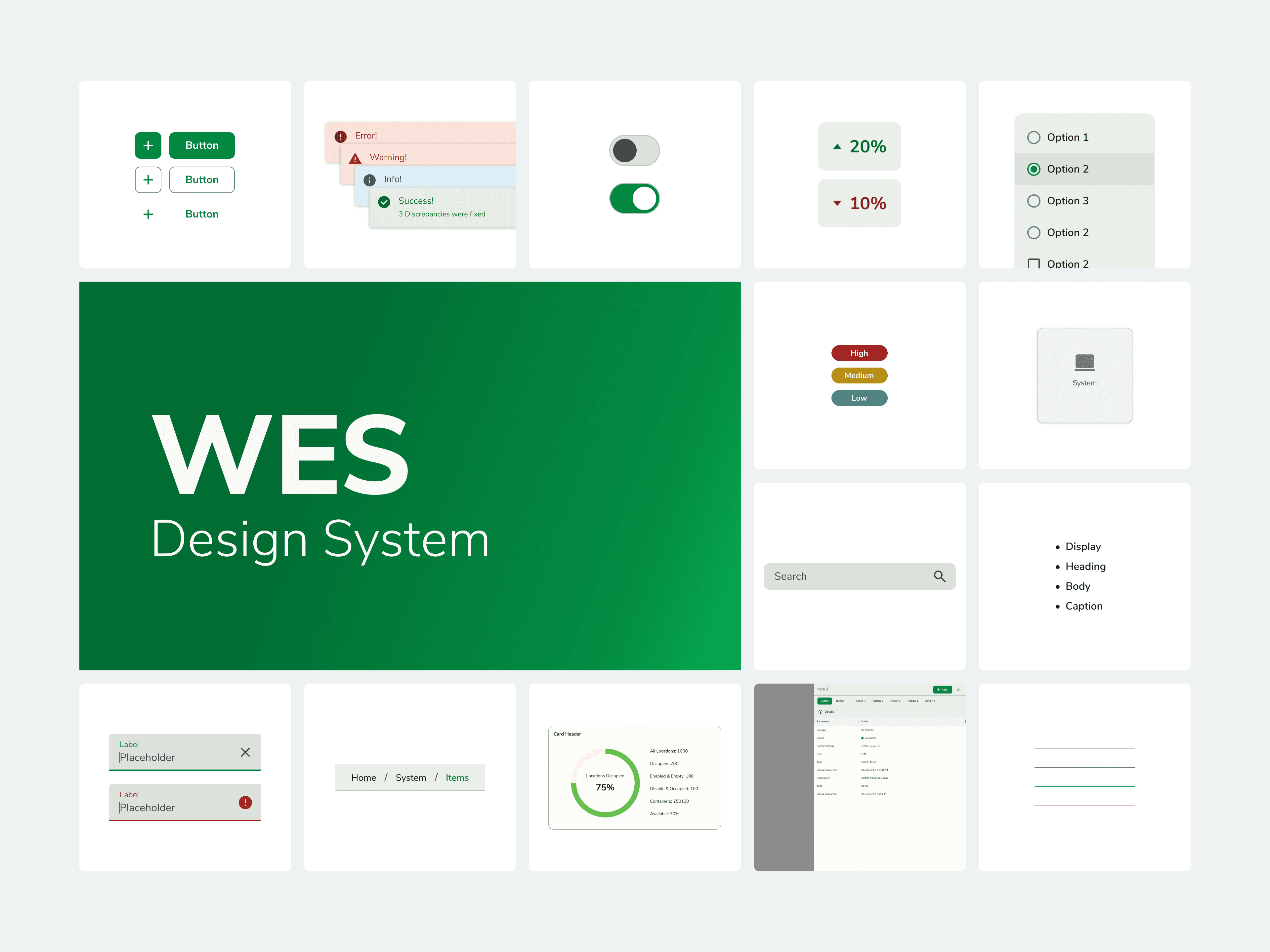

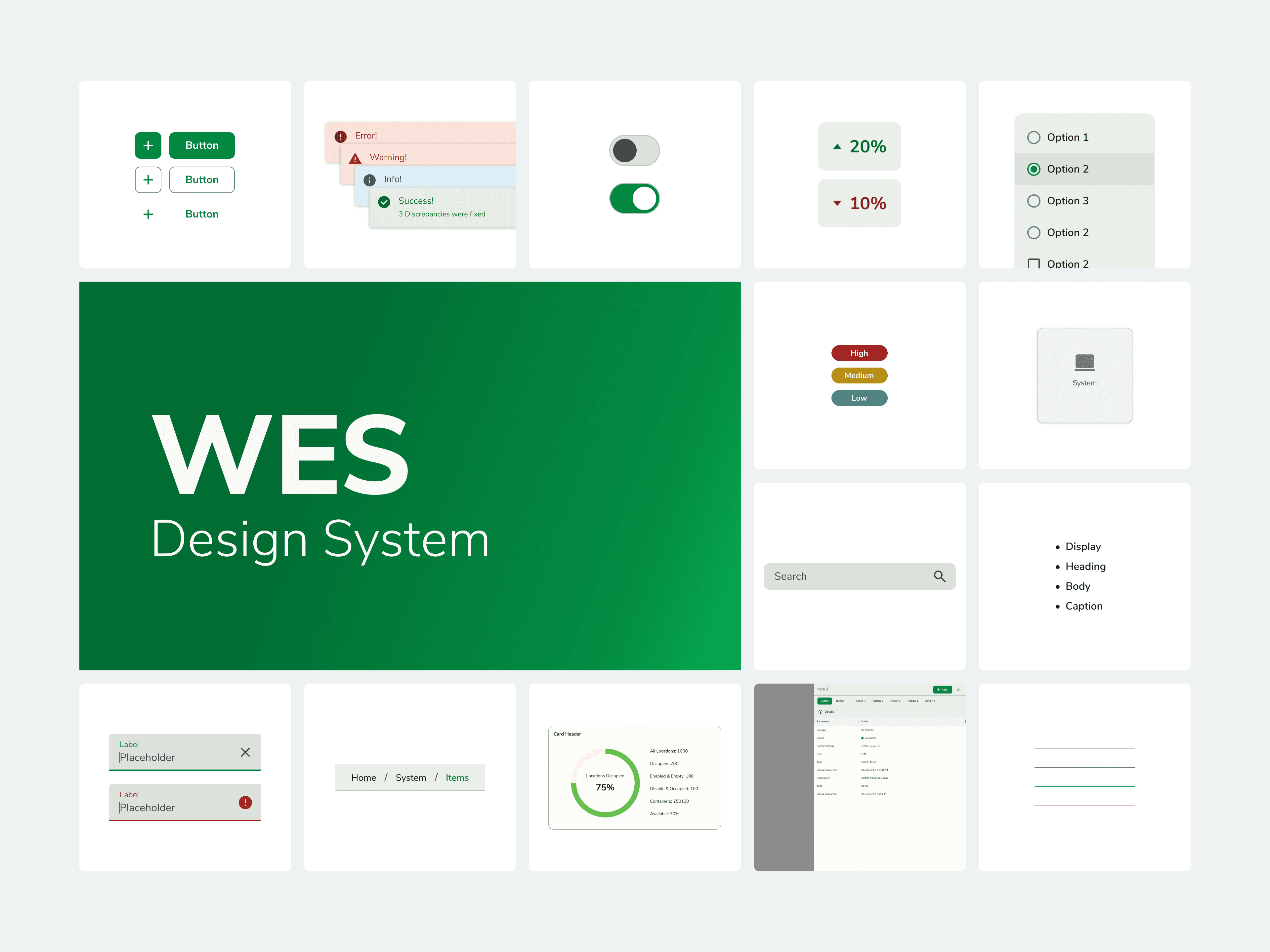

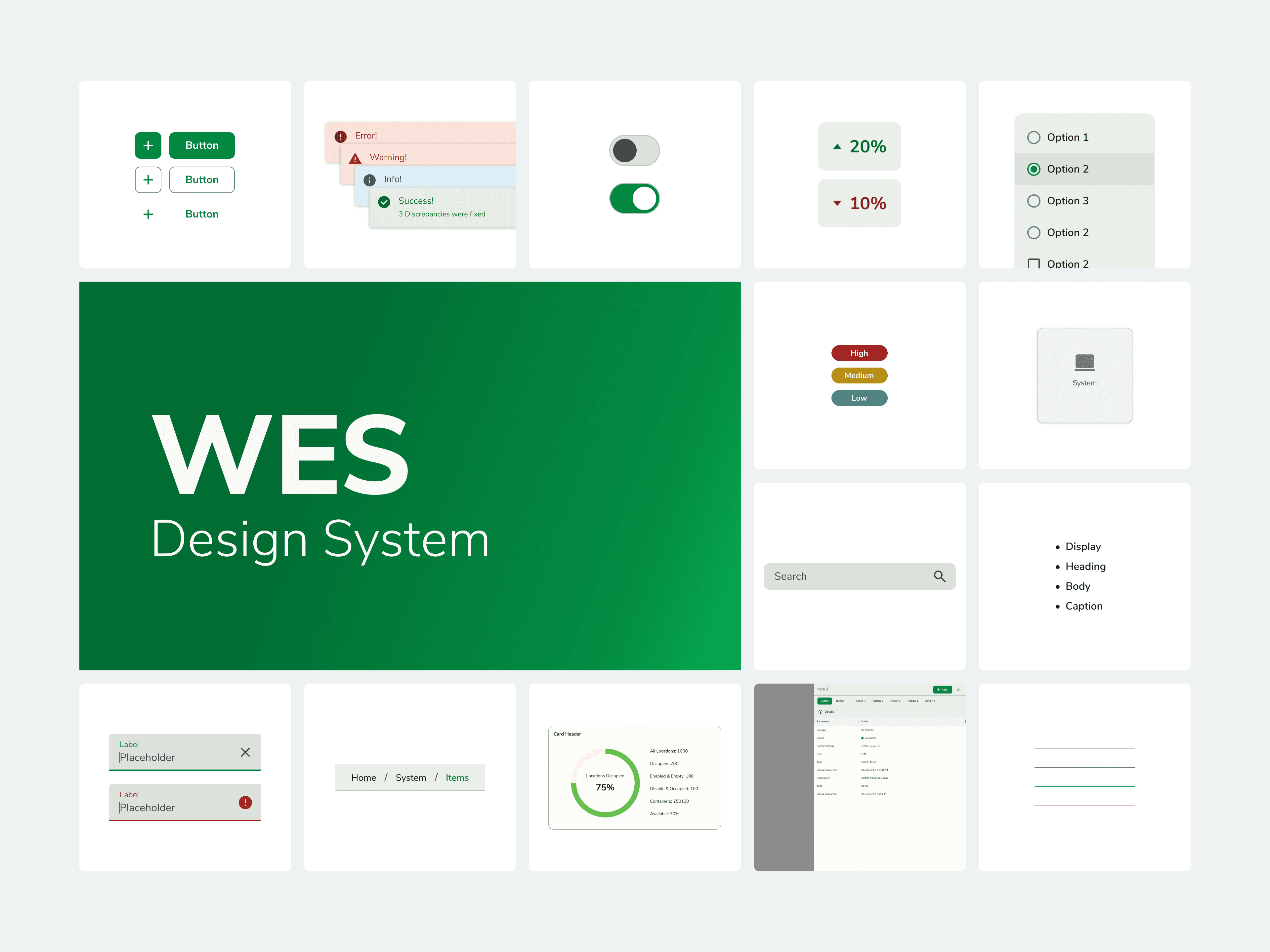

Building WES Design System: From Fragmented UI to a Scalable System

Building WES Design System: From Fragmented UI to a Scalable System

Building WES Design System: From Fragmented UI to a Scalable System

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

Designing a guided picking experience for warehouse operators

Designing a guided picking experience for warehouse operators

Designing a guided picking experience for warehouse operators

Designing a step-by-step experience that reduces errors, speeds up picking, and supports operators in high-pressure environments.

Designing a step-by-step experience that reduces errors, speeds up picking, and supports operators in high-pressure environments.

Designing a step-by-step experience that reduces errors, speeds up picking, and supports operators in high-pressure environments.

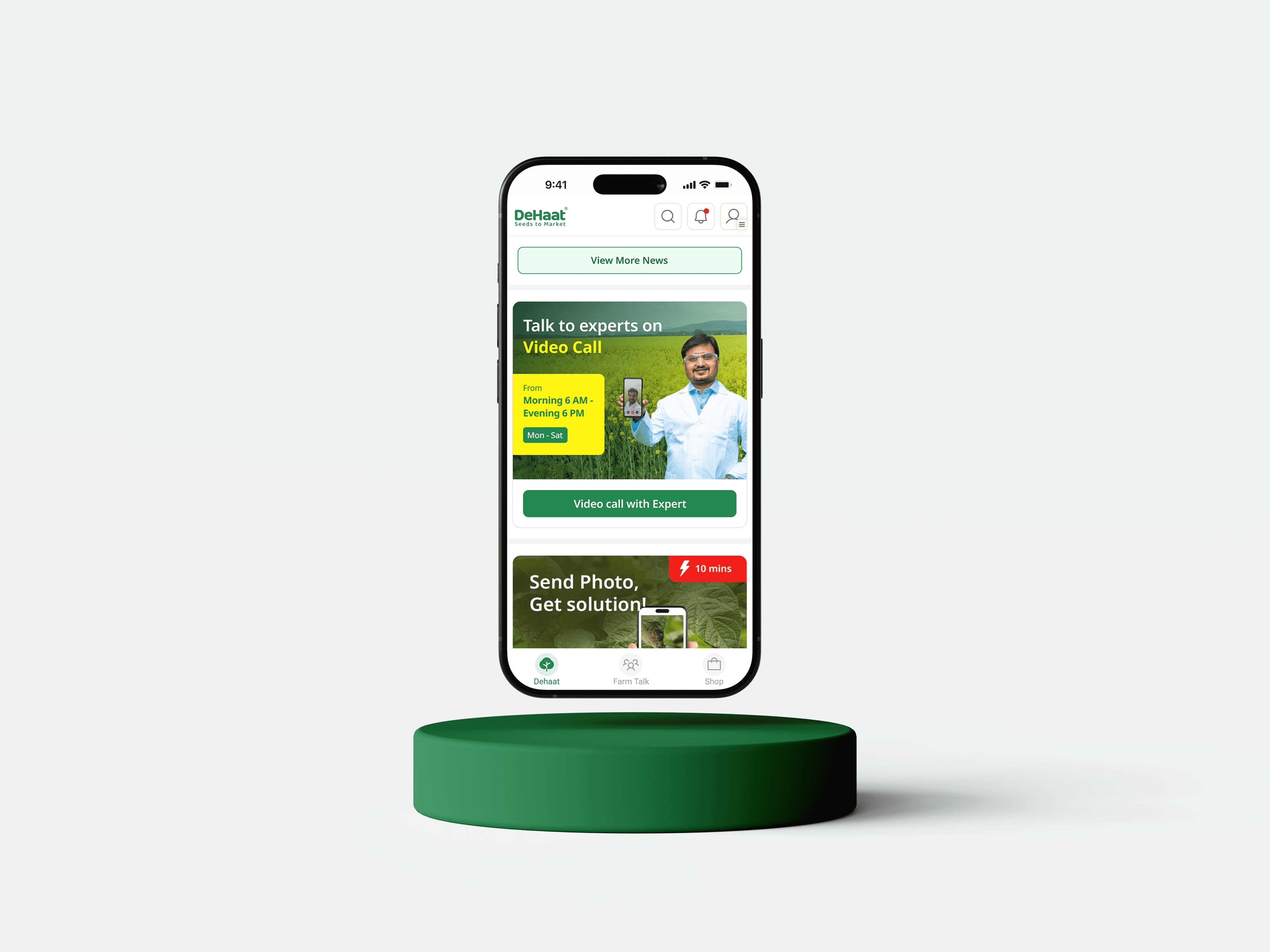

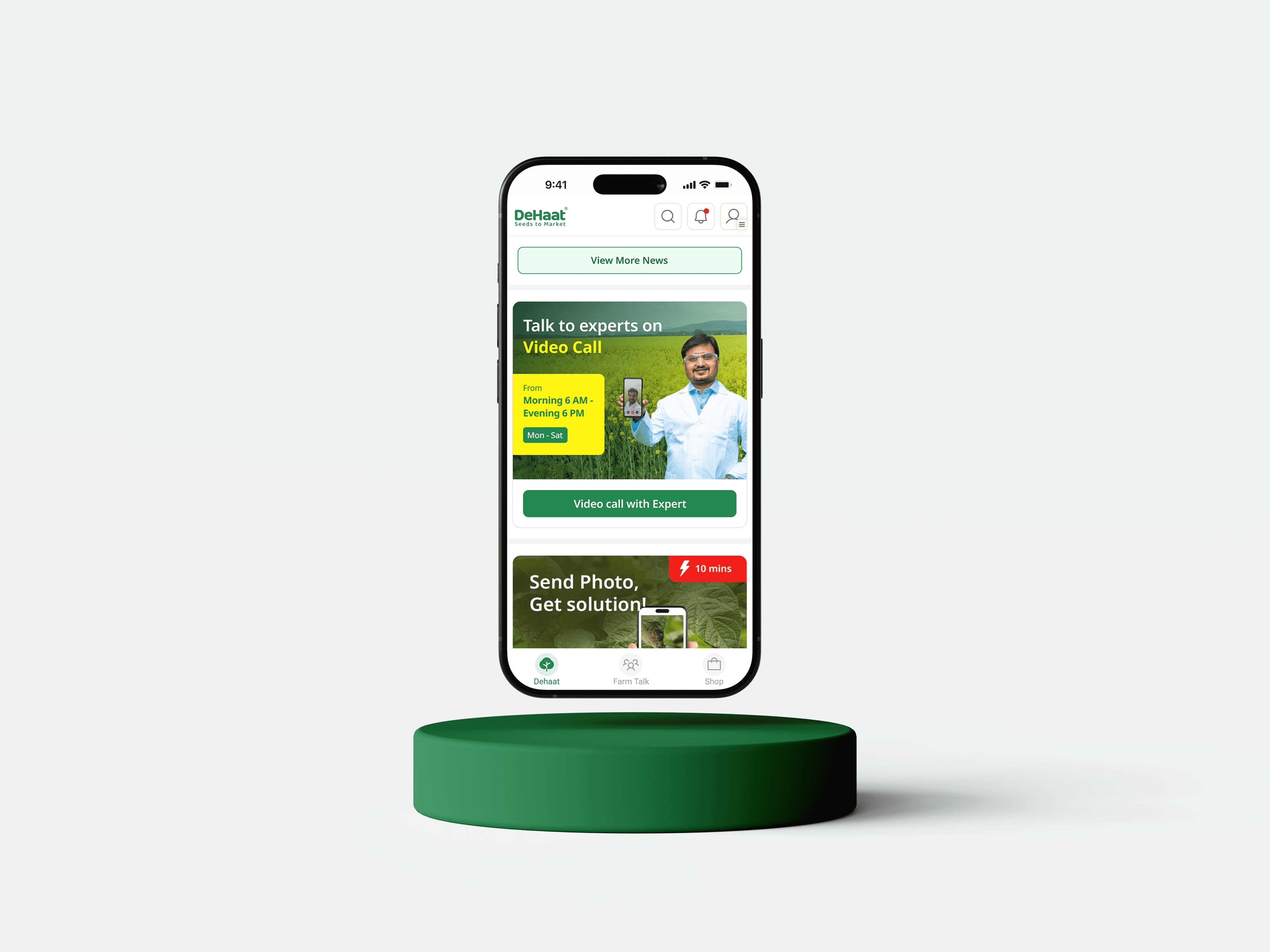

Helping farmers make confident buying decisions

Helping farmers make confident buying decisions

Helping farmers make confident buying decisions

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.