Designing a guided picking experience for warehouse operators

Designing a step-by-step experience that reduces errors, speeds up picking, and supports operators in high-pressure environments.

Role

Product Designer

Industry

Logistics

Duration

2 months

Overview

Overview

Context

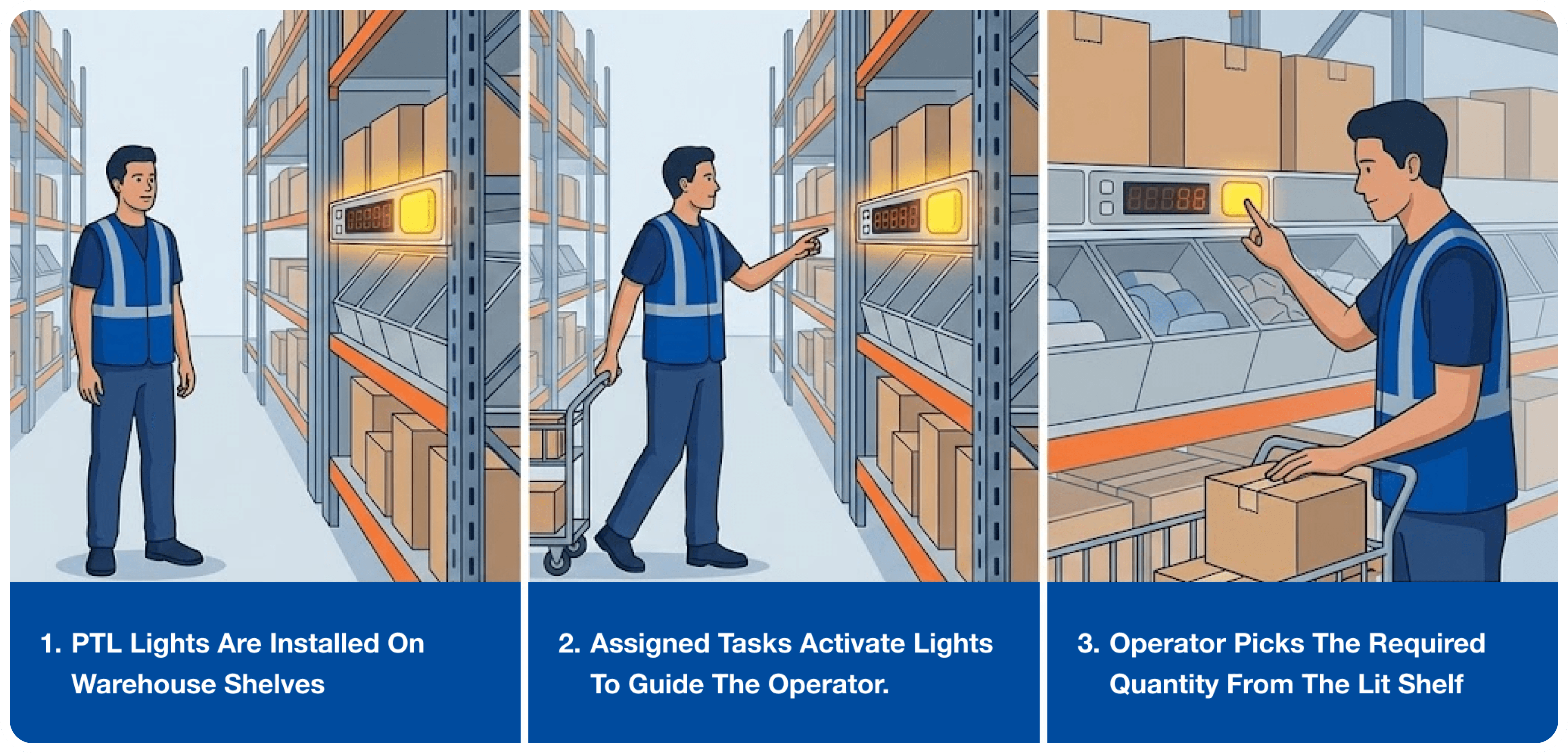

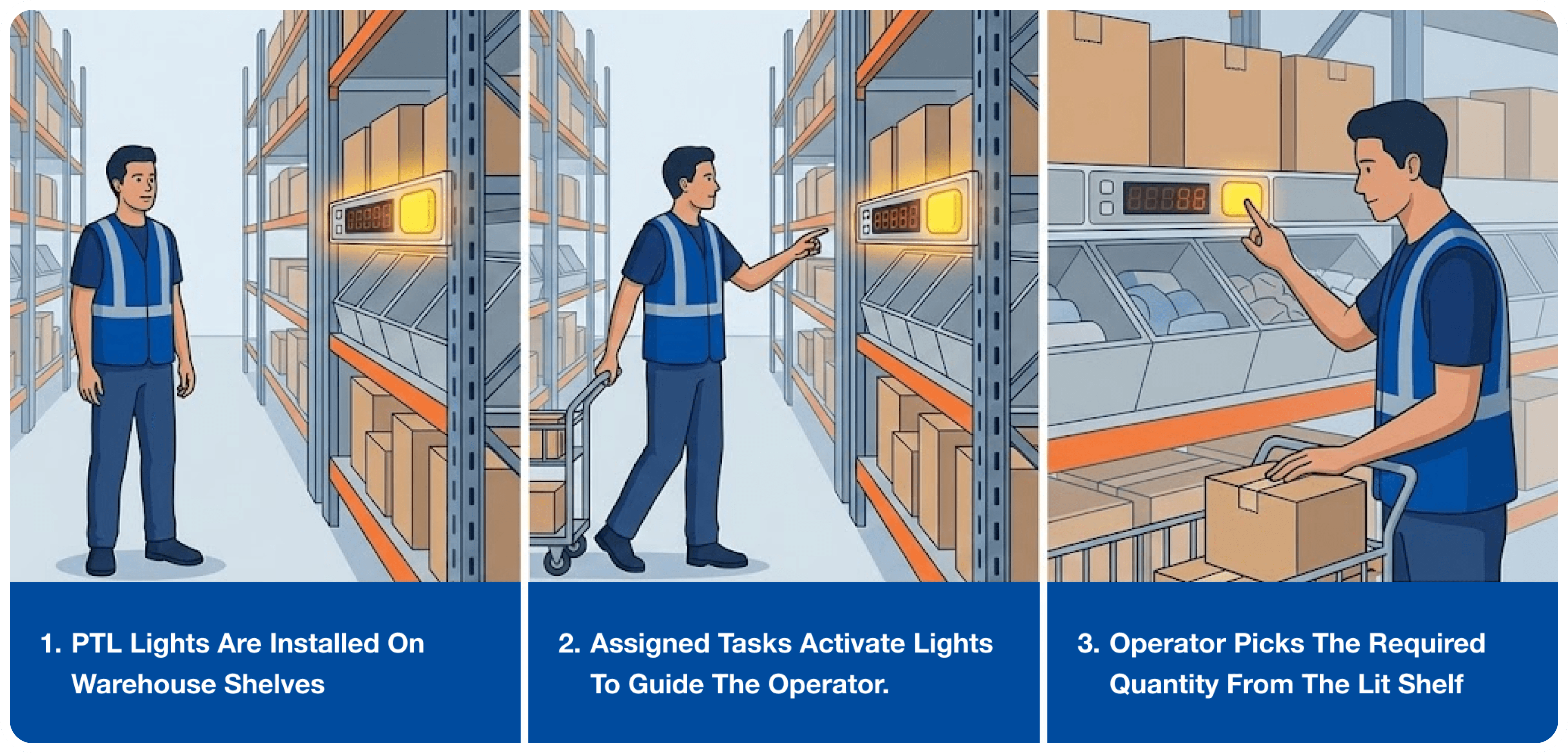

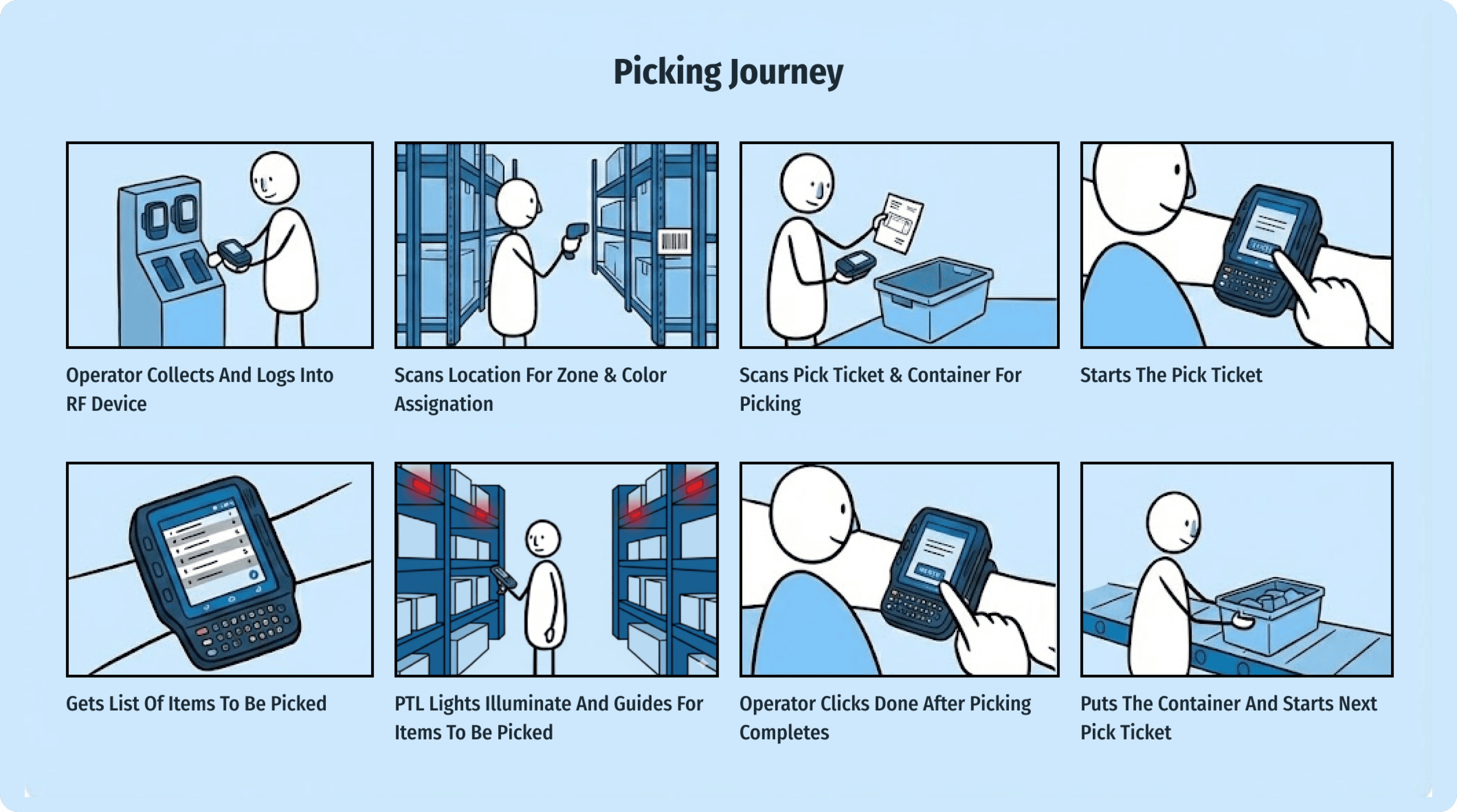

StoreSolutions is a US-based B2B warehousing and distribution solutions provider offering end-to-end supply chain consulting. They were launching a new service offering: Pick-to-Light (PTL) capability.

In high-volume fulfillment centers, warehouse operators rely on PTL systems (rack-mounted lights) that guide them to the correct pick locations. However, while PTL indicated where to pick, operators still depended on RF handheld devices to know what to pick, how much, and to manage exceptions, resulting in context switching and inefficiencies.

Note: StoreSolutions is a pseudonym. The actual client name has been replaced in this project to protect client confidentiality.

Context

StoreSolutions is a US-based B2B warehousing and distribution solutions provider offering end-to-end supply chain consulting. They were launching a new service offering: Pick-to-Light (PTL) capability.

In high-volume fulfillment centers, warehouse operators rely on PTL systems (rack-mounted lights) that guide them to the correct pick locations. However, while PTL indicated where to pick, operators still depended on RF handheld devices to know what to pick, how much, and to manage exceptions, resulting in context switching and inefficiencies.

Note: StoreSolutions is a pseudonym. The actual client name has been replaced in this project to protect client confidentiality.

Problem

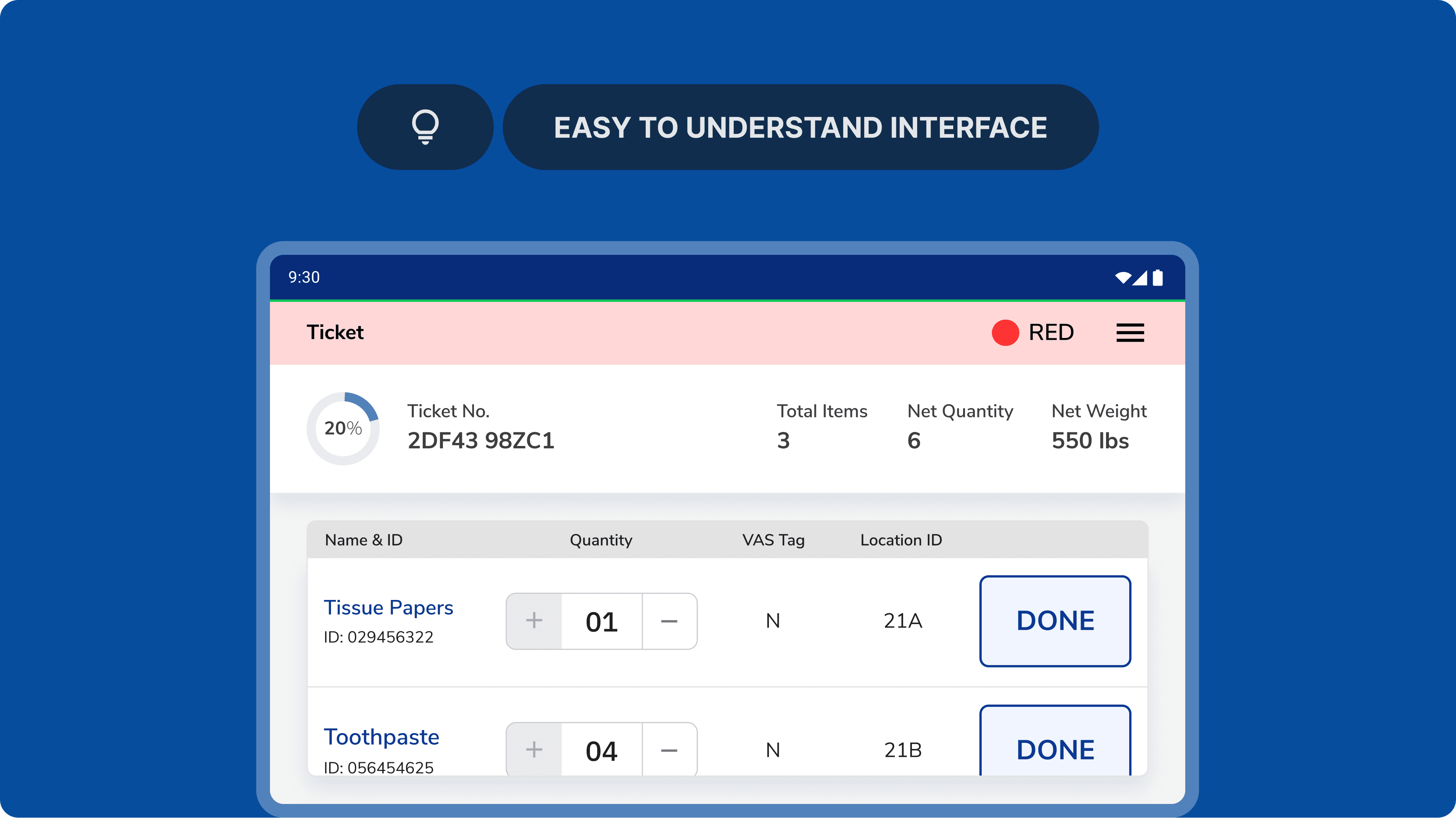

Warehouse picking operators needed a clear and reliable RF device experience to pick items accurately in fast-paced, high-volume environments, where even small errors can disrupt warehouse operations.

The challenge was to design for speed, accuracy, and low cognitive load with limited prior knowledge of real-world picking workflows and very few existing references for RF device interfaces.

Problem

Warehouse picking operators needed a clear and reliable RF device experience to pick items accurately in fast-paced, high-volume environments, where even small errors can disrupt warehouse operations.

The challenge was to design for speed, accuracy, and low cognitive load with limited prior knowledge of real-world picking workflows and very few existing references for RF device interfaces.

Outcome & Impact

Designed and delivered a context-aware RF interface, validated through UAT with 125 concurrent operators over 6+ hours, confirming usability and performance at scale. The design delivered:

Lower cognitive load through guided steps, simplified confirmations, and consistent response times (~0.8–0.9s), reducing hesitation and mis-picks.

Fast, predictable feedback with core picking actions responding in under ~1 second, enabling uninterrupted, high-speed workflows.

Error-free critical flows, achieving a 0% functional error rate across full, partial, zero-pick, and multi-operator scenarios.

Outcome & Impact

Designed and delivered a context-aware RF interface, validated through UAT with 125 concurrent operators over 6+ hours, confirming usability and performance at scale. The design delivered:

Lower cognitive load through guided steps, simplified confirmations, and consistent response times (~0.8–0.9s), reducing hesitation and mis-picks.

Fast, predictable feedback with core picking actions responding in under ~1 second, enabling uninterrupted, high-speed workflows.

Error-free critical flows, achieving a 0% functional error rate across full, partial, zero-pick, and multi-operator scenarios.

Research & Insights

Design workshops were conducted with Product Manager as well as other stakeholders to understanding the workflows and requirements. Apart from this, secondary research was also conducted to understand the domain better. Below are the key insights:

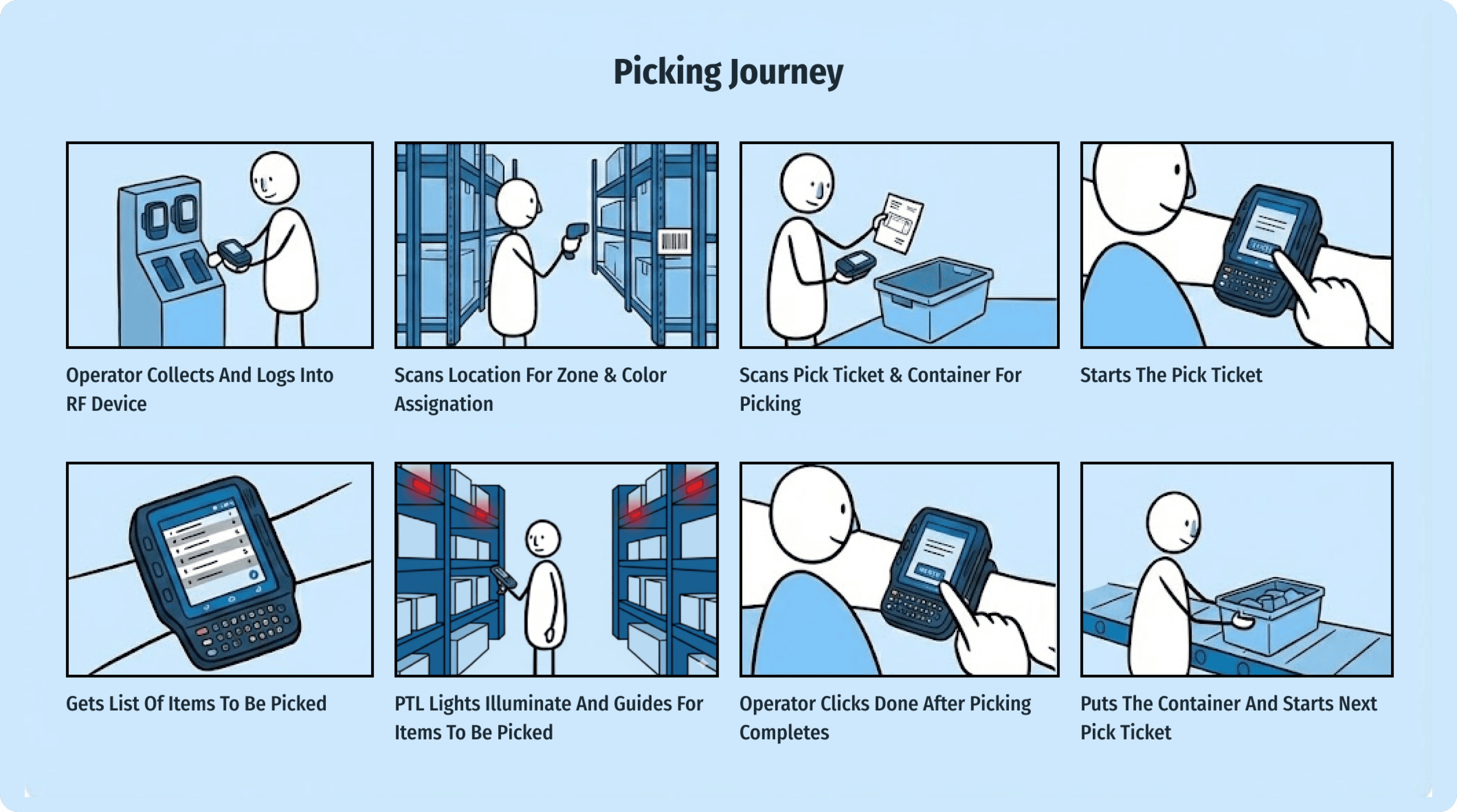

Operators prioritize speed, certainty, and consistency, relying on muscle memory during high-throughput picking, which demands minimal cognitive effort.

Interactions often occur while handling physical load and wearing gloves, requiring glanceable cues and bigger interaction targets.

Clear confirmation and error-recovery states are critical to maintaining trust across workflows, outweighing happy-path optimization.

Environmental constraints such as noise, variable lighting, fatigue, and data-dense screens required high visual clarity and scalable, system-led design.

Research & Insights

Design workshops were conducted with Product Manager as well as other stakeholders to understanding the workflows and requirements. Apart from this, secondary research was also conducted to understand the domain better. Below are the key insights:

Operators prioritize speed, certainty, and consistency, relying on muscle memory during high-throughput picking, which demands minimal cognitive effort.

Interactions often occur while handling physical load and wearing gloves, requiring glanceable cues and bigger interaction targets.

Clear confirmation and error-recovery states are critical to maintaining trust across workflows, outweighing happy-path optimization.

Environmental constraints such as noise, variable lighting, fatigue, and data-dense screens required high visual clarity and scalable, system-led design.

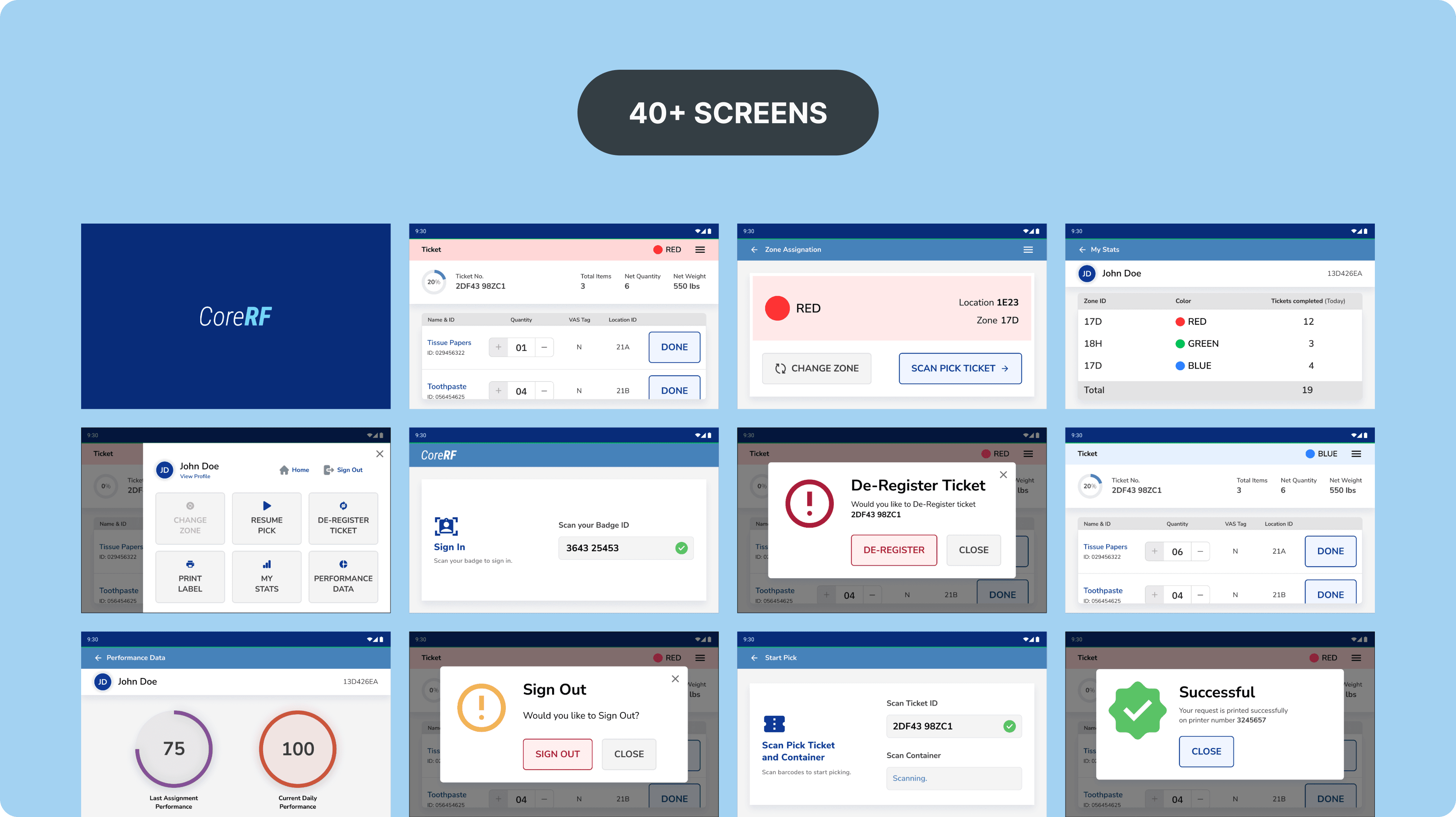

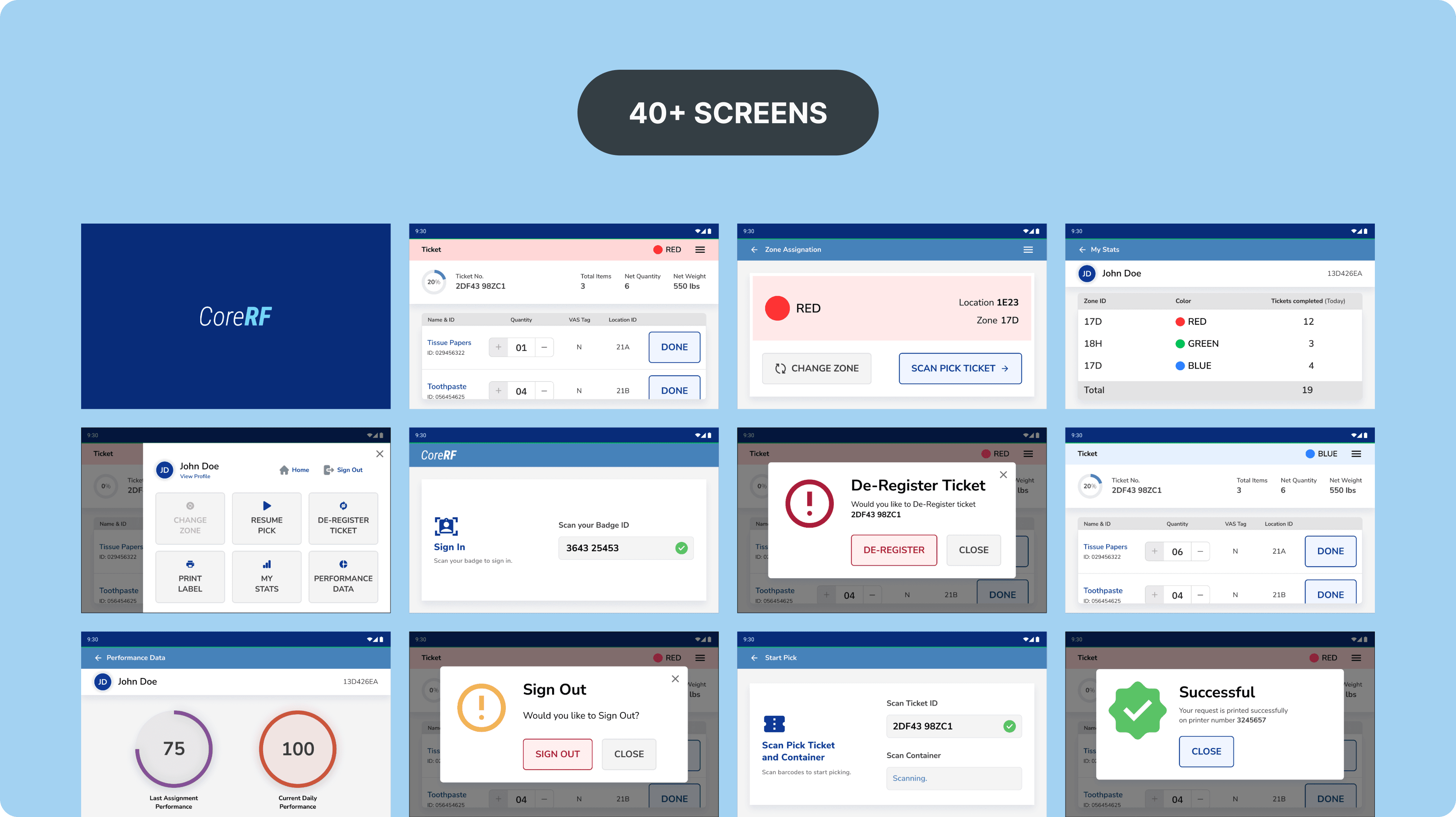

Solution Highlights

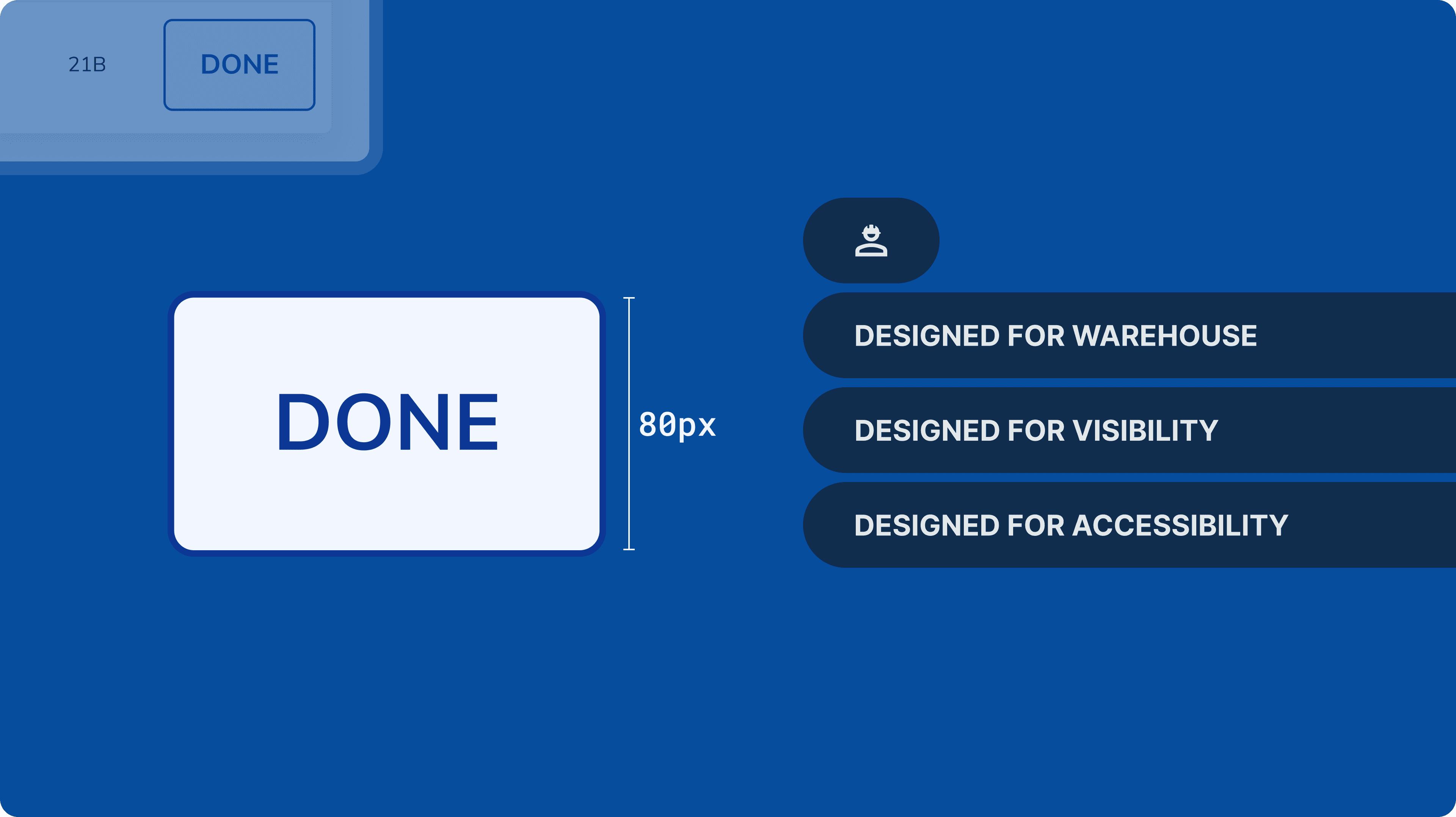

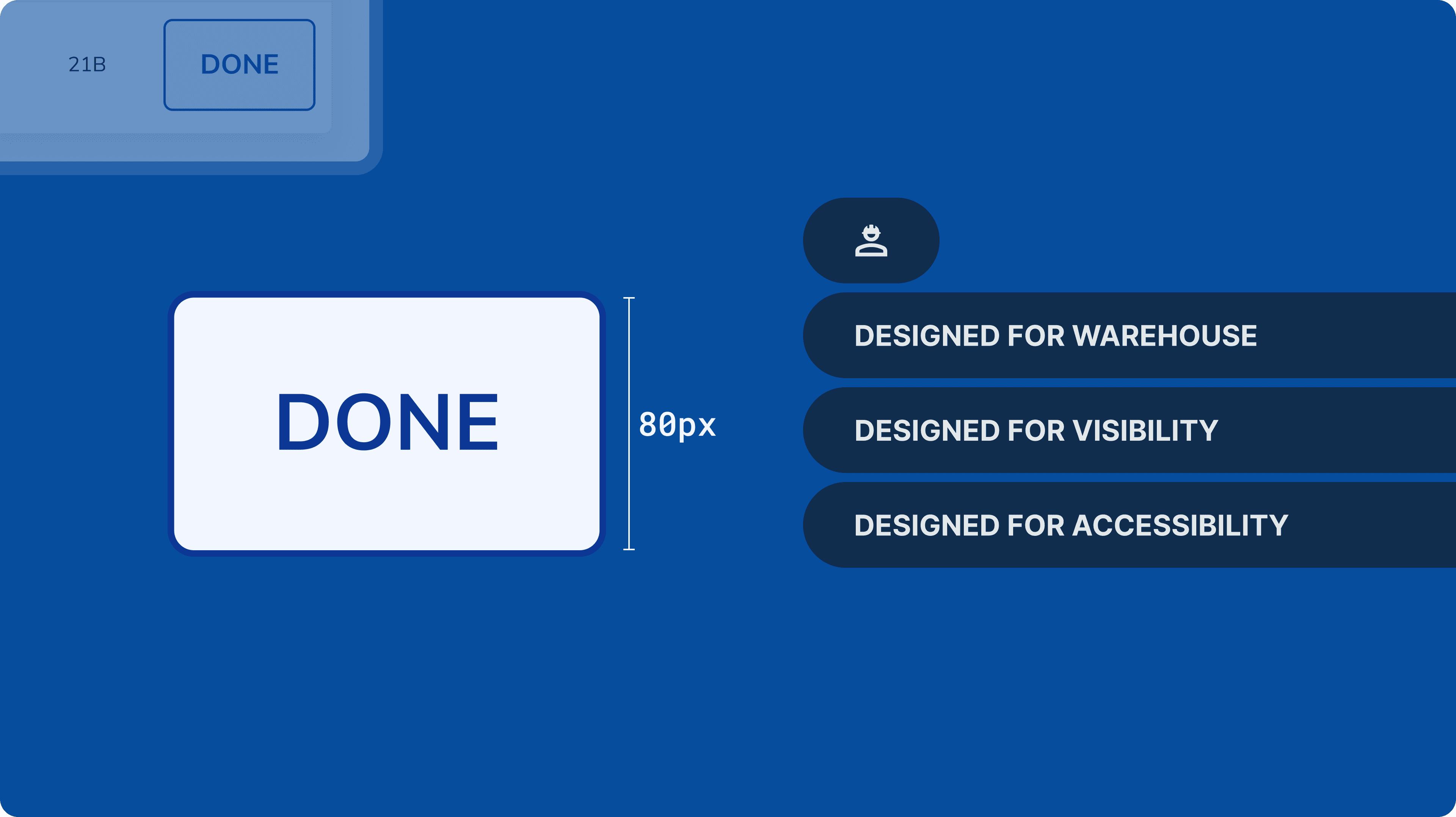

High-Confidence Primary Actions: Oversized, clearly labeled actions reduce errors during fast-paced warehouse tasks.

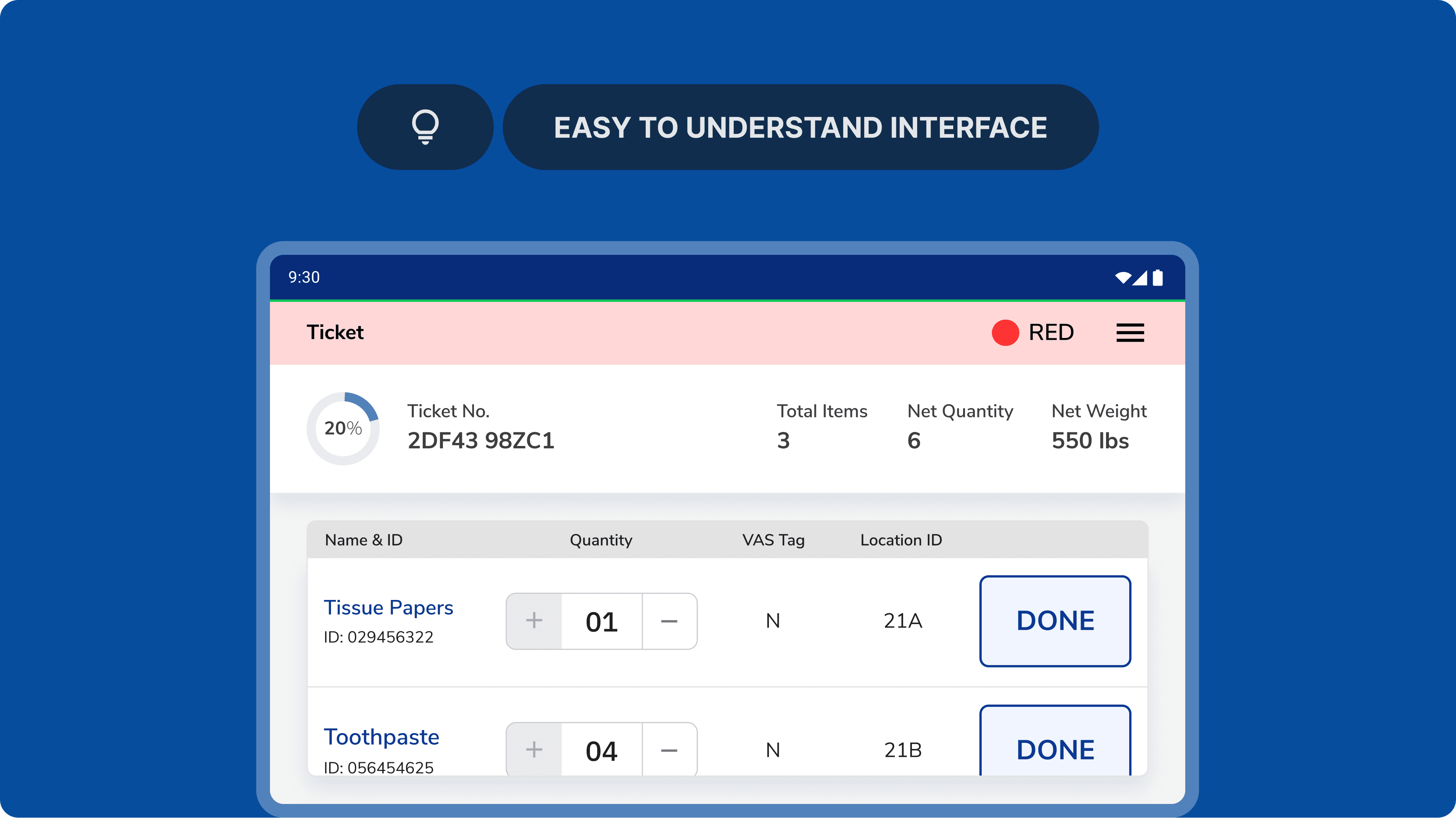

Clear Information Hierarchy: Critical details are surfaced first to enable quick understanding and decision-making.

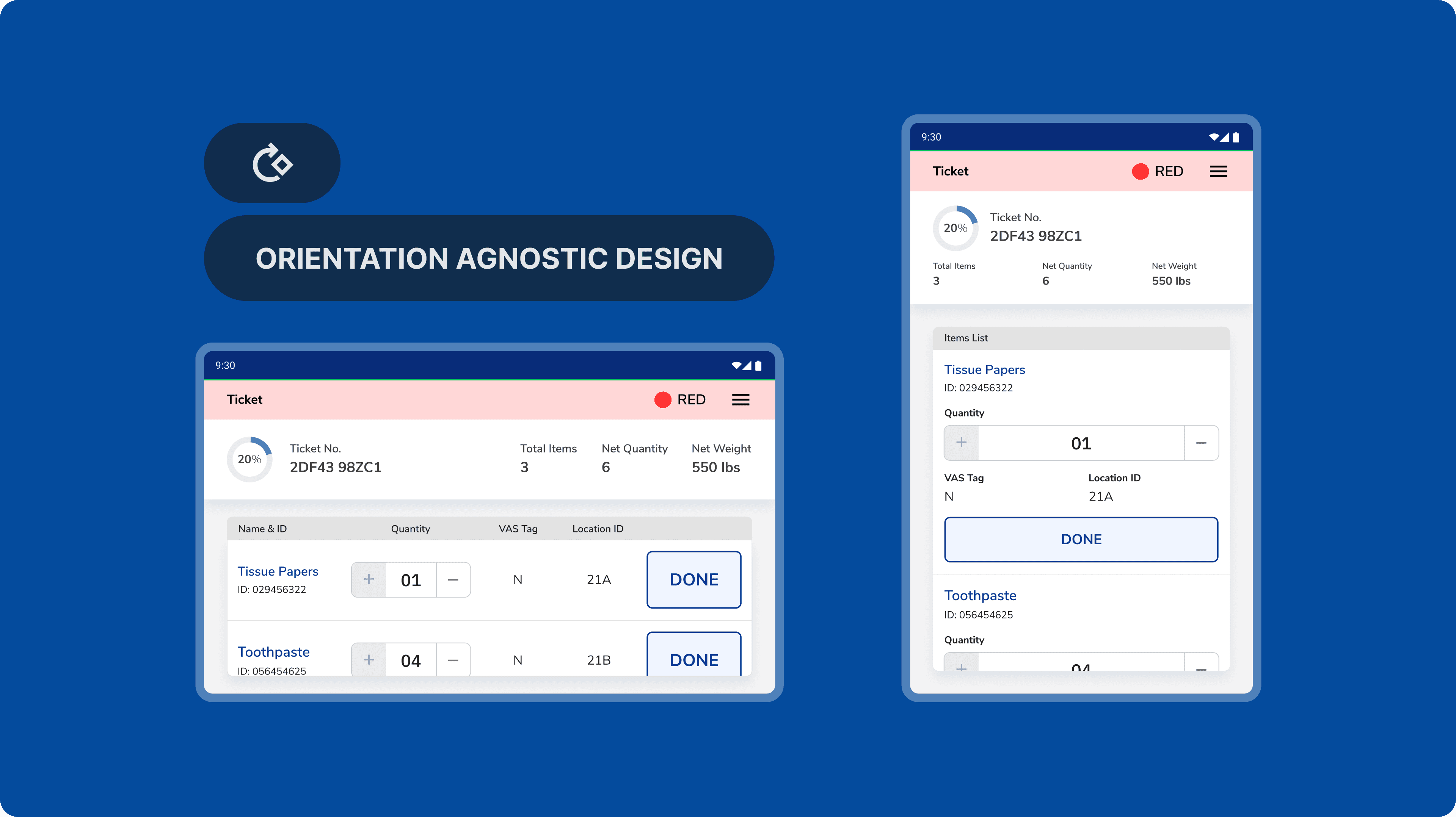

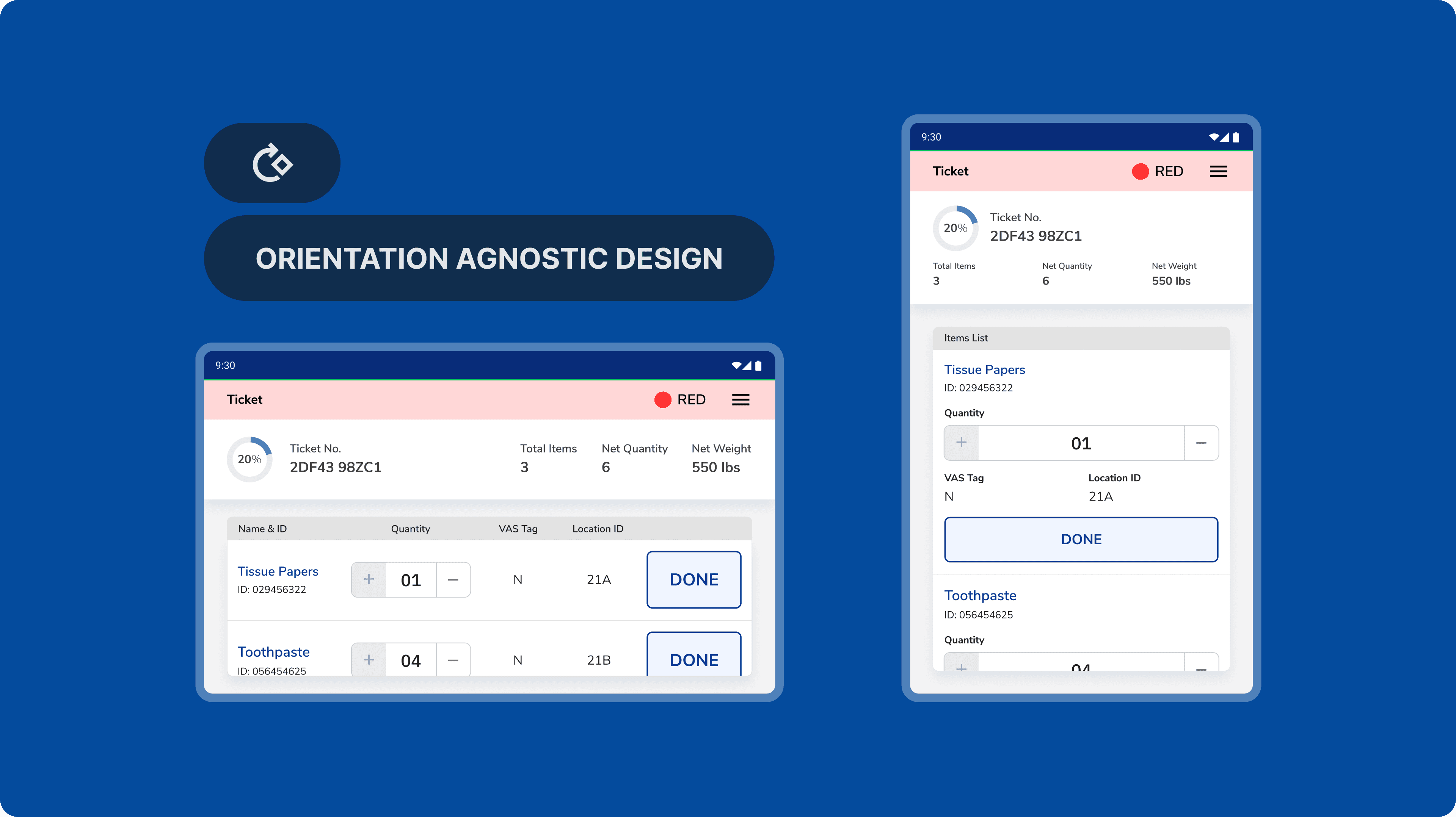

Orientation-Agnostic Layout: Consistent usability across orientations ensures uninterrupted operations on the floor.

Solution Highlights

High-Confidence Primary Actions: Oversized, clearly labeled actions reduce errors during fast-paced warehouse tasks.

Clear Information Hierarchy: Critical details are surfaced first to enable quick understanding and decision-making.

Orientation-Agnostic Layout: Consistent usability across orientations ensures uninterrupted operations on the floor.

Key Takeaways

Designing for physical environments: Learned to design for movement, gloves, lighting, and fatigue—not just screen interactions.

Clarity over density on small screens: Had to be ruthless with information hierarchy to keep RF screens readable and cognitively light.

Preventing errors over fixing them: Focused on eliminating mistakes upfront, since even small errors can disrupt warehouse operations.

Other projects

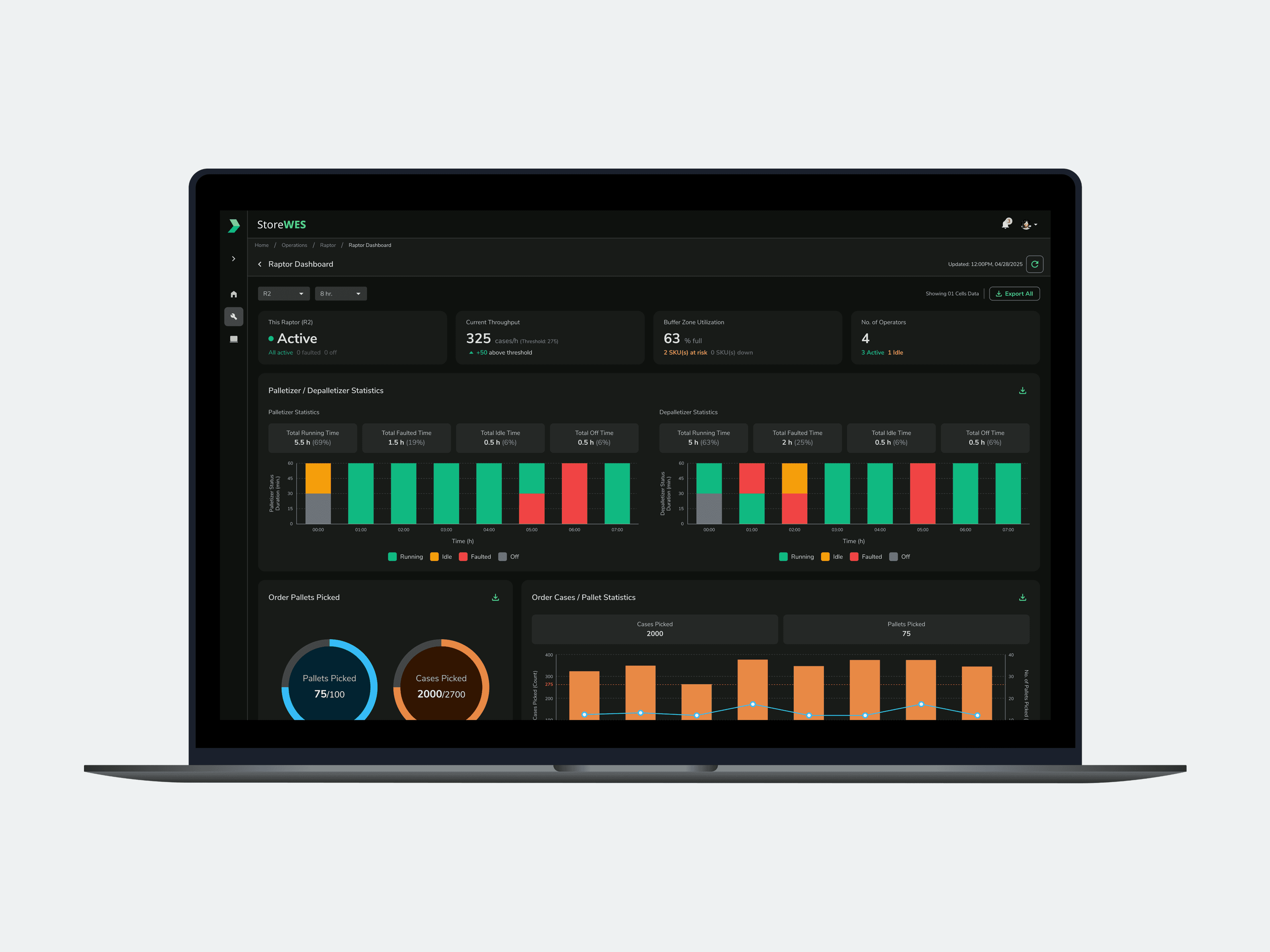

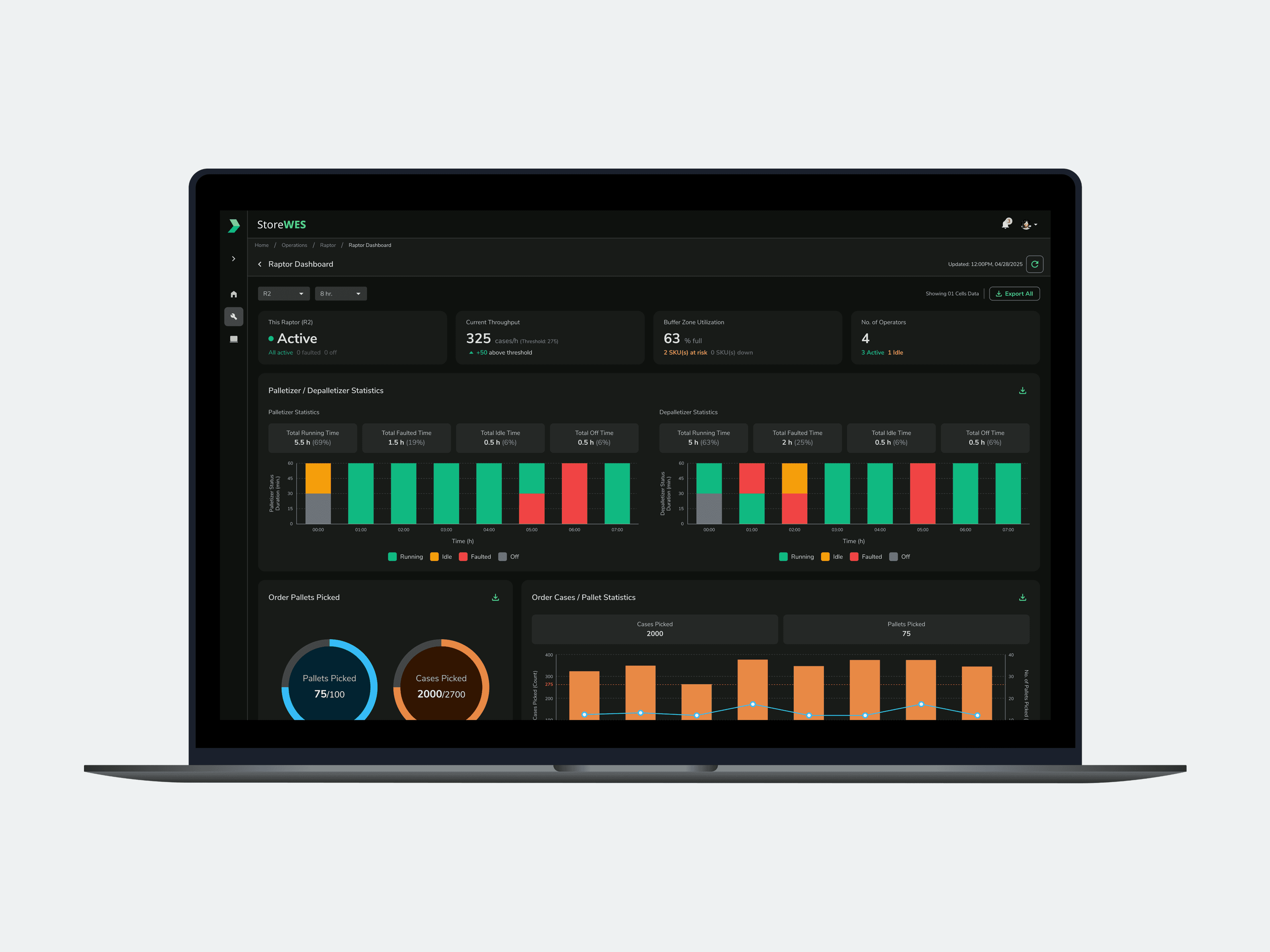

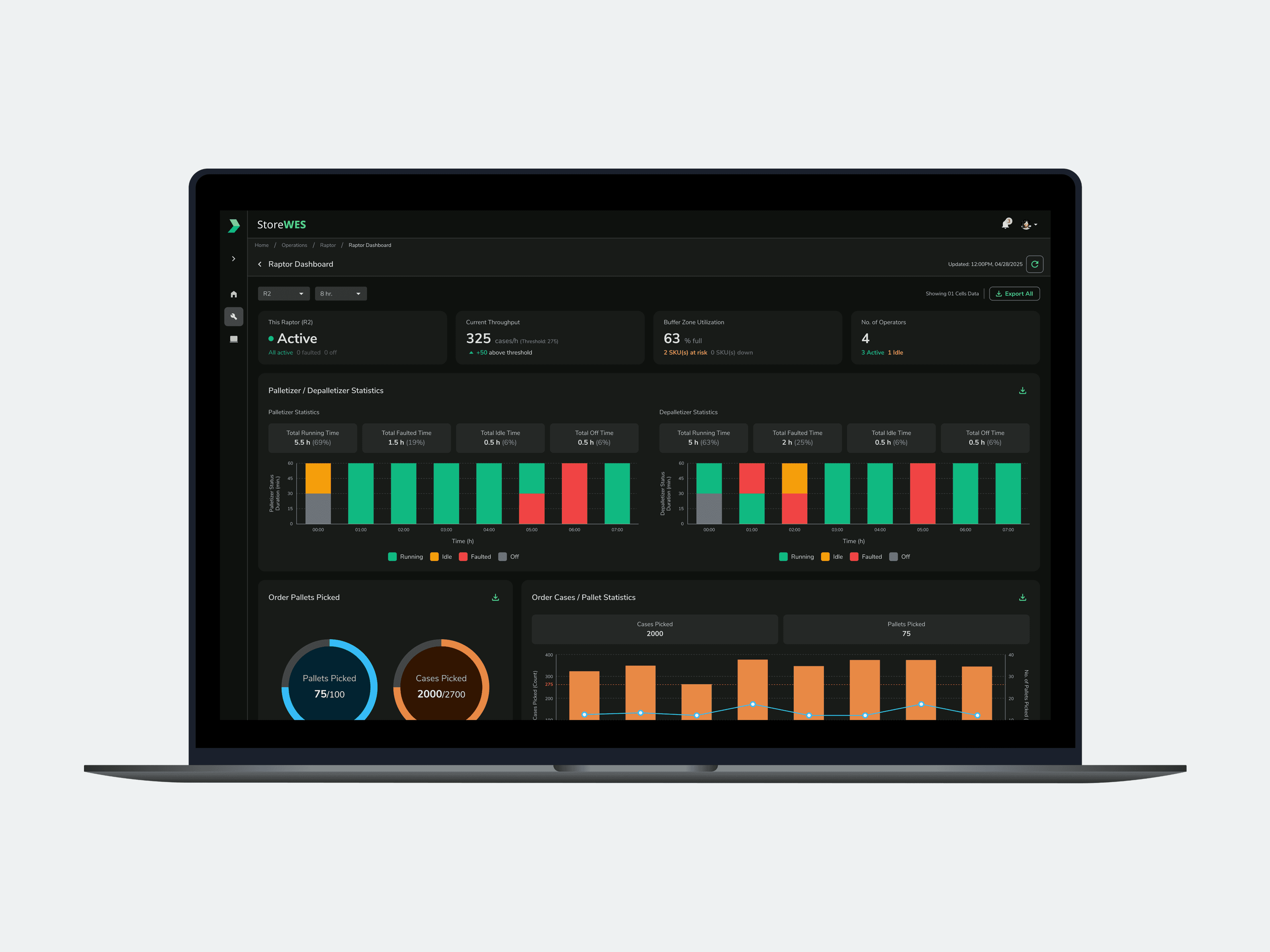

Making Robotic Fulfillment Understandable for Warehouse Supervisors

Making Robotic Fulfillment Understandable for Warehouse Supervisors

Making Robotic Fulfillment Understandable for Warehouse Supervisors

Designing clear, actionable insights that help supervisors monitor, understand, and manage robotic operations with confidence.

Designing clear, actionable insights that help supervisors monitor, understand, and manage robotic operations with confidence.

Designing clear, actionable insights that help supervisors monitor, understand, and manage robotic operations with confidence.

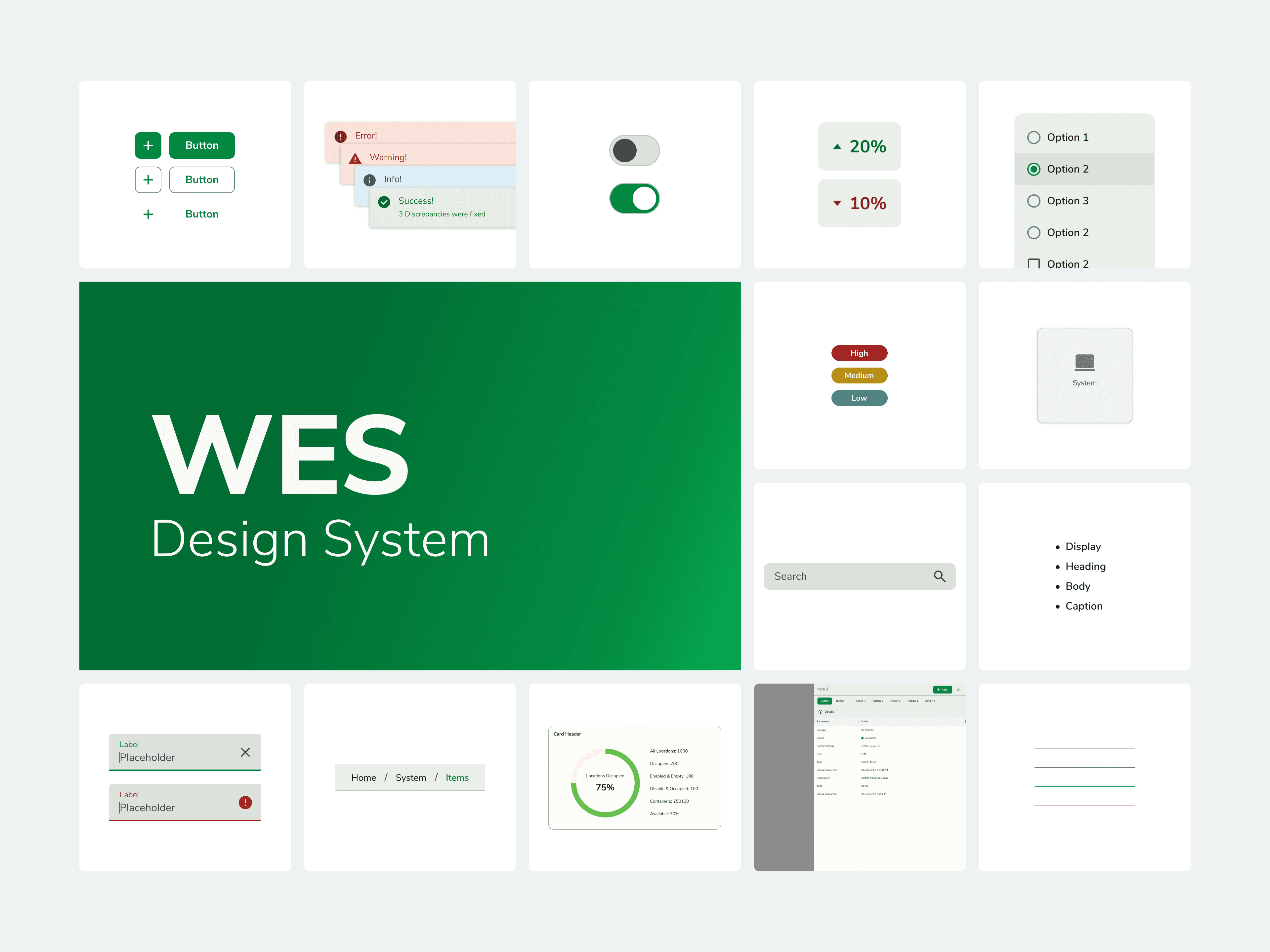

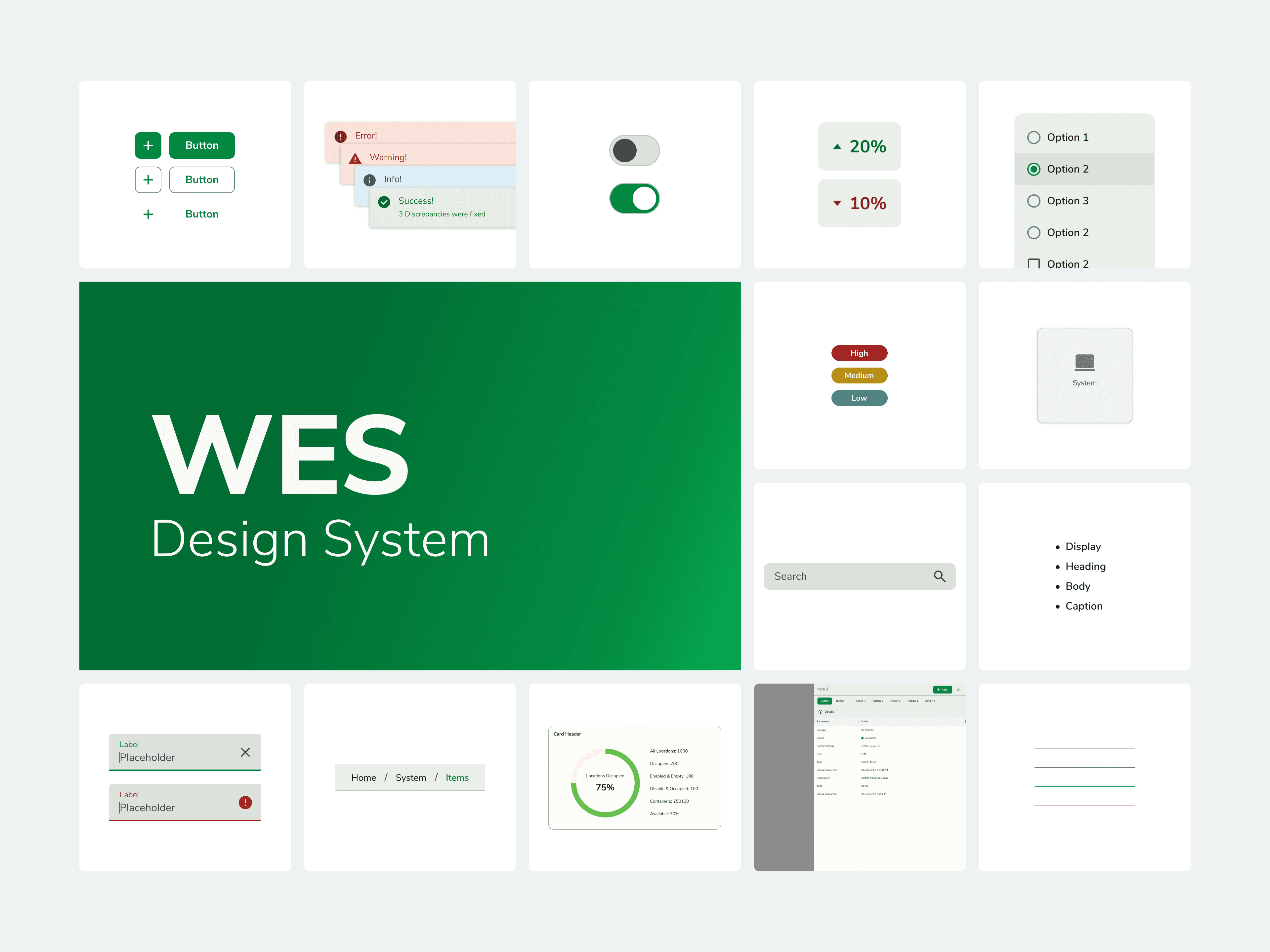

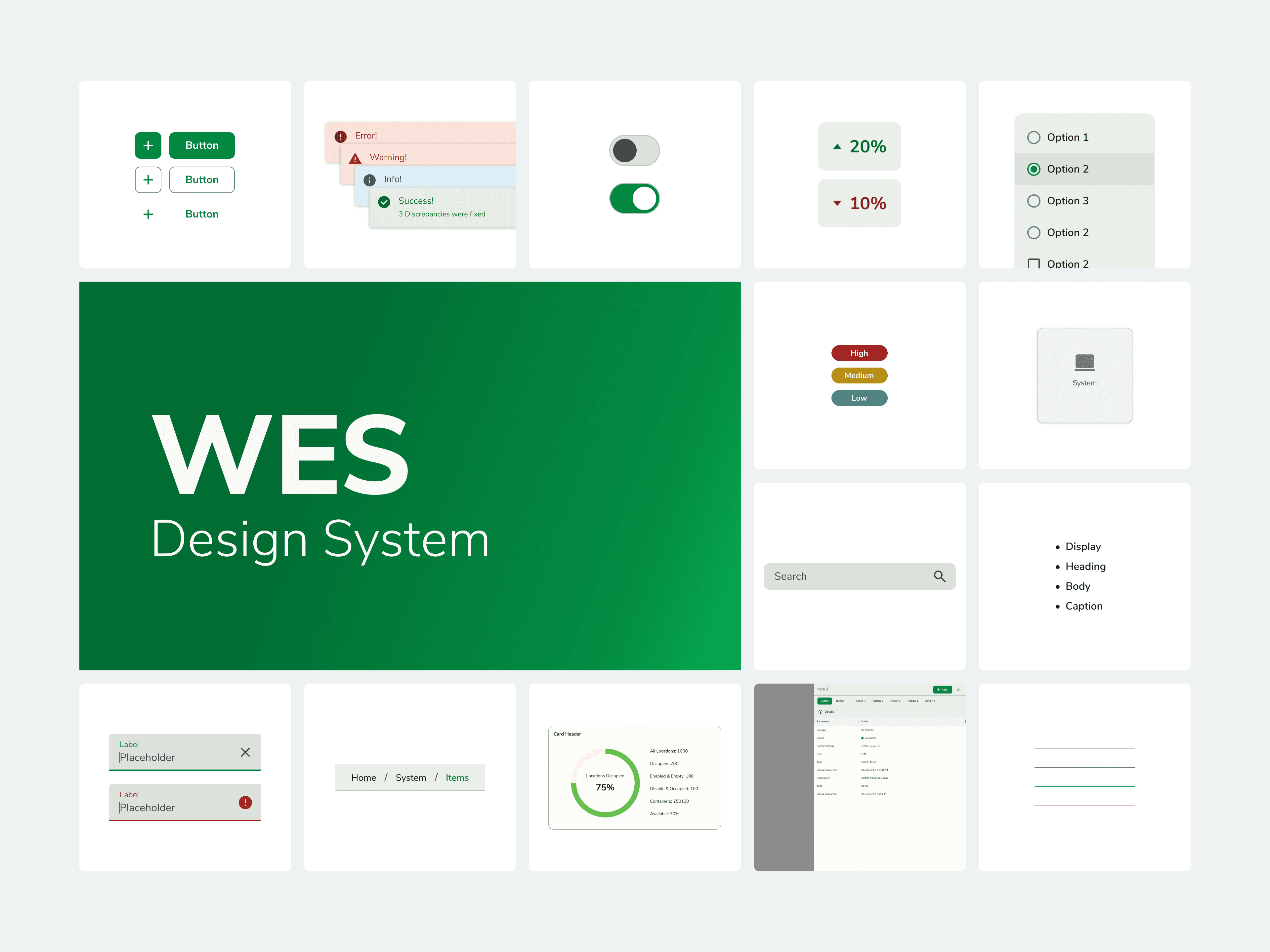

Building WES Design System: From Fragmented UI to a Scalable System

Building WES Design System: From Fragmented UI to a Scalable System

Building WES Design System: From Fragmented UI to a Scalable System

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

Designing a unified, token-driven system that improves consistency, accelerates delivery, and scales across themes.

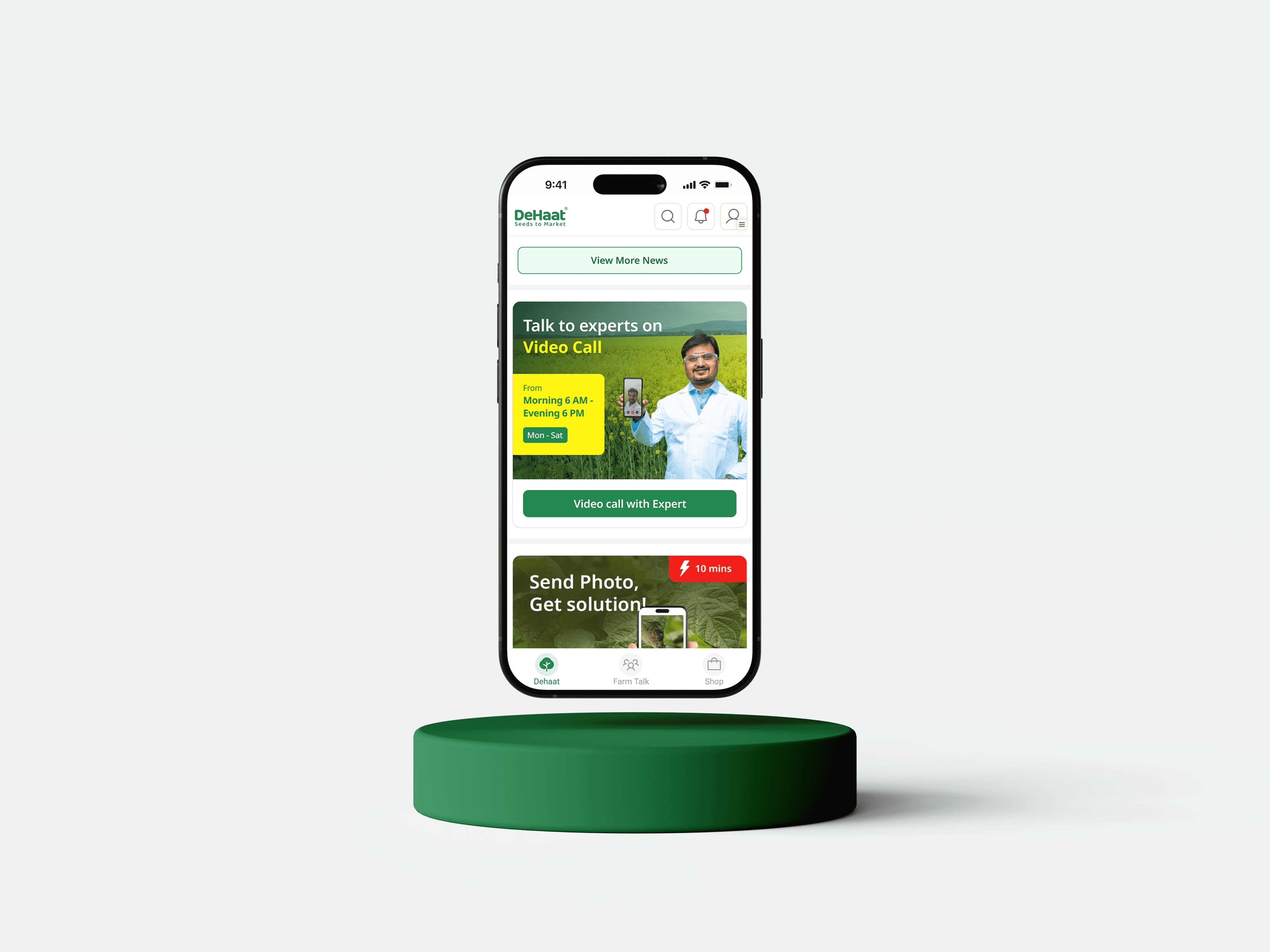

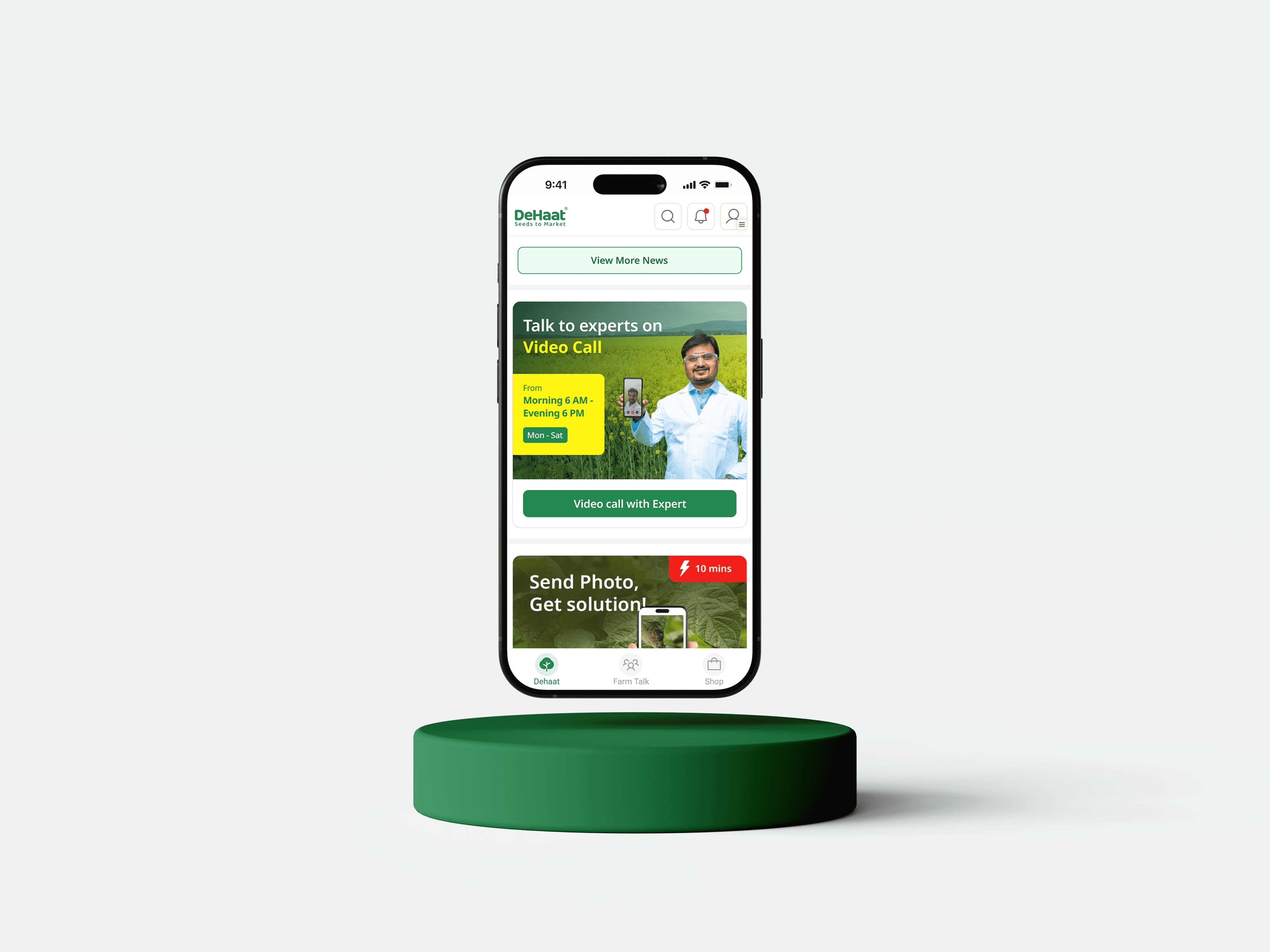

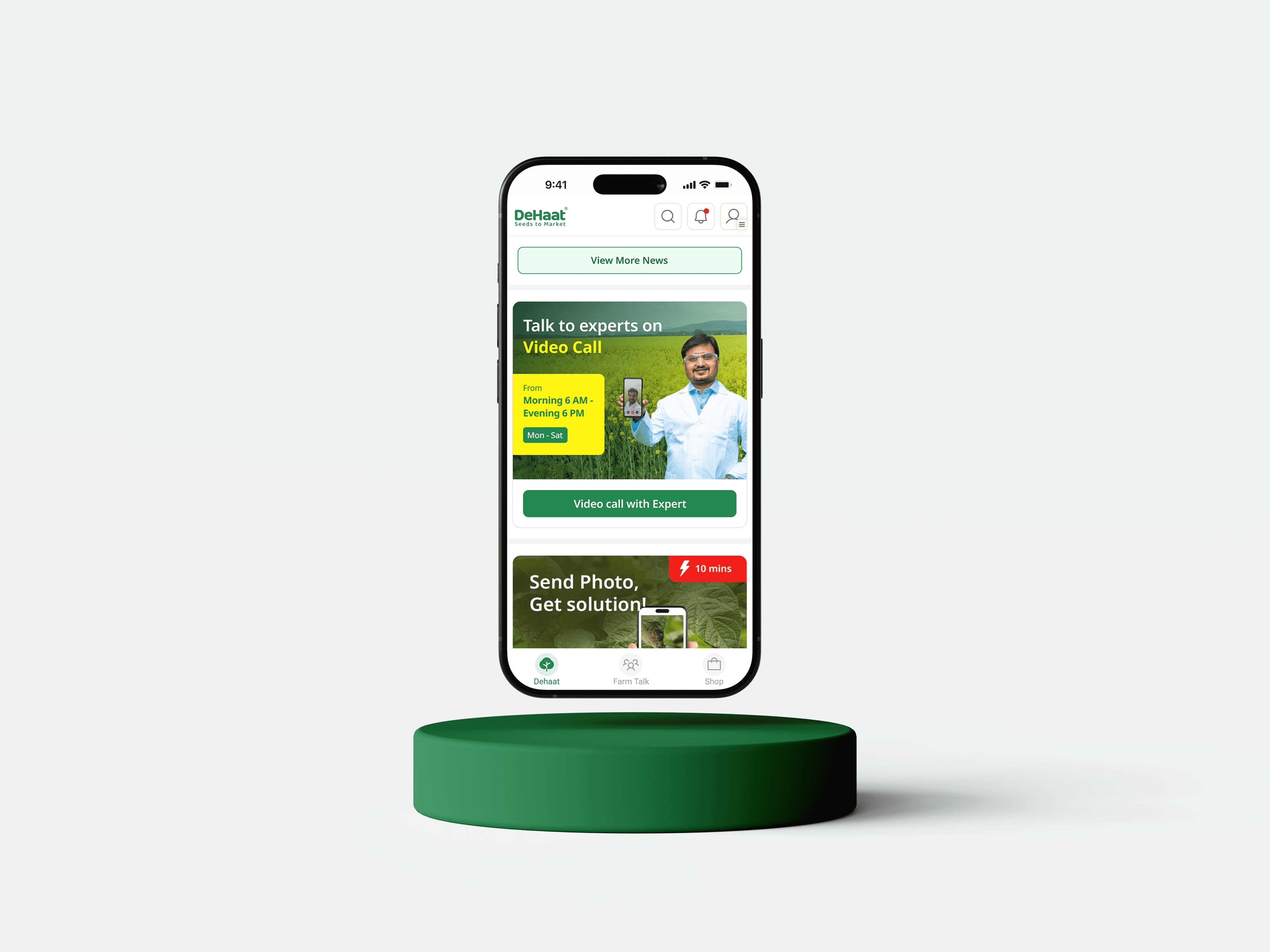

Helping farmers make confident buying decisions

Helping farmers make confident buying decisions

Helping farmers make confident buying decisions

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.

Designing an experience that empowers farmers with clear information and expert guidance when it matters most.